Advantages and Disadvantages of Common Fibers

Plant fibers are generally resistant to alkali but not acid. The acid and alkali resistance of hemp is stronger than that of cotton fiber, and the wet strength will increase. Simple identification method: it burns quickly, has the smell of burning paper, and leaves less ash, which is gray-white.

Cotton fiber: good hygroscopicity, high wet strength, soft hand feel, easy to wrinkle, general ironing temperature is 190-210℃.

Hemp fiber: good hygroscopicity, high wet strength, fast heat dissipation, poor elasticity, easy to wrinkle, rough feel, generally used in blending, ironing temperature is 190-210℃.

Animal fibers are generally resistant to acid but not alkali. The acid resistance of wool is slightly stronger than that of silk, and the wet strength will be reduced. Simple identification method: it burns slowly, bubbles and carbonizes while shrinking, has the smell of burning hair, is gray in black, and is crispy and easy to crush.

Wool fiber: has good hygroscopicity, moisture retention, warmth retention, elasticity, and dyeability. It is not resistant to alkali and oxidants. It is easy to turn yellow under ultraviolet rays. The ironing temperature is 160-180°C.

Silk fiber: bright luster, good hygroscopicity, elasticity, and dyeability. It is not resistant to alkali, oxidants, and salt water. It is easy to turn yellow under ultraviolet rays. The ironing temperature is 160-180°C.

Man-made fibers are roughly divided into three types: rayon, rayon and artificial wool. Common varieties include viscose fiber, acetate fiber, cupro fiber, etc. Viscose fiber has many characteristics similar to cotton. It is resistant to alkali but not acid, has good hygroscopicity and dyeability, but has low strength, low wet strength, and is not resistant to washing. The ironing temperature is 120-160°C. Acetate fiber is not as resistant to acid and alkali as cellulose fiber. It burns slowly, has an acetic acid smell, and the ashes are black and hard and brittle. However, its feel and gloss are comparable to silk, and it is elastic. The ironing temperature is 110-130°C.

There are many types of synthetic fibers, which generally have good stability and unique properties in some aspects. For example:

Polyester has high abrasion resistance, acid and alkali resistance, dripping and drawing when burning, and a fragrant smell. The ashes are dark brown and are not easy to crush. However, polyester has poor hygroscopicity and is not easy to dye. It is usually blended with other fibers and the ironing temperature is 140-150℃;

Nylon has high strength, best wear resistance, light weight, good elasticity and is not easy to wrinkle. It is resistant to alkali but not acid. Its burning phenomenon is similar to polyester. It is a good fiber for sports fabrics. The ironing temperature is 120-130℃;

Acrylic fiber has the best light resistance, is fluffy, soft and warm, but has poor heat resistance and is prone to pilling. It is generally made into artificial wool-like fabrics. Acrylic has a pungent smell when burned, the flame is bright, and the ashes are black and hard and can be crushed. Its ironing temperature is 130-140℃;

Vinyl is the most corrosion-resistant and has the best hygroscopicity among chemical fibers, but it is not resistant to moisture and heat. Generally used in military camouflage and industrial fabrics, its ironing temperature is 120-140℃;

Polypropylene is light in weight, high in strength, and has stable performance, but has poor heat resistance (easy to shrink above 100°C) and poor dyeing performance. The ironing temperature is 90-100°C;

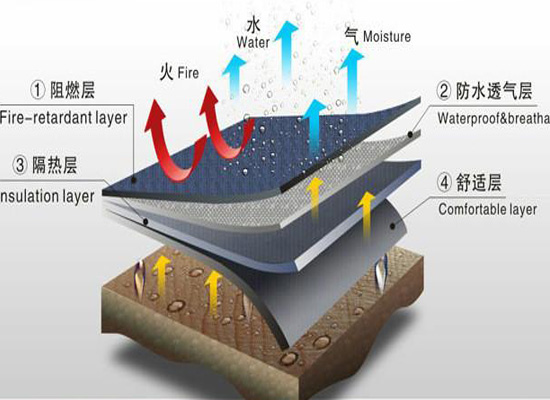

Chlorine fiber is not easy to burn. It shrinks and softens when it is close to the flame. It will extinguish itself and form hard lumps when it is away from the flame. It will shrink above 70℃. It is generally blended with other materials. It is mostly used in flame-retardant fabrics and cannot be ironed;

Spandex has high elasticity and the burning ashes are sticky. It is mostly used in fabrics that require elasticity. The ironing temperature is 90-110℃.