Understand aramid fiber in one article

Understand Aramid Fiber

in one article

1. Aramid fiber

The full name of aramid fiber is aromatic polyamide fiber. It is a linear polymer composed of aromatic groups and amide groups. It has excellent mechanical properties, stable chemical structure, ideal mechanical properties, ultra-high strength and high modulus. , high temperature resistance, acid and alkali resistance, light weight, wear resistance and other excellent properties.

Compared with ordinary flexible polymer molecular chains, the main chain structure of aramid fiber is mainly composed of a rod-shaped molecular structure formed by paraposition of benzene rings. Due to the presence of large conjugated benzene rings, internal rotation of molecular segments is difficult, thus presenting a linear rigid structure. This rigid molecular chain easily forms a liquid crystal form and achieves high modulus. During the spinning process, this structure can also be stacked in high-density multilayers along the fiber orientation in a limited space, giving the polymer higher strength.

2. Classification of aramid fiber

According to different chemical structures, aramid fibers are divided into para-aramid, meta-aramid and heterocyclic aramid. Among them, para-aramid and meta-aramid have a wider application range.

1. Para-aramid 1414

Para-aramid is also known as polyparaphenylene terephthalamide fiber (PPTA) and polyparabenzamide fiber (PBA). It is obtained by low-temperature solution polycondensation in N-methylpyrrolidone (NMP)-calcium chloride using p-phenylenediamine and terephthaloyl chloride as monomer raw materials.

The main chain structure is mainly composed of a rod-shaped molecular structure formed by the paraposition of benzene rings. Due to the presence of large conjugated benzene rings, internal rotation of molecular segments is difficult, thus presenting a linear rigid structure.

2. Meta-aramid 1313

Meta-aramid is also known as poly-m-phenylene isophthalamide (PMTA) fiber. It is produced by using m-phenylenediamine and isophthaloyl chloride as raw materials through polymerization reaction, neutralization reaction, spinning and other process steps.

Compared with para-aramid, the molecular chain covalent bond of meta-aramid has no conjugation effect, the rotation potential within the molecular chain is lower than that of para-aramid, the flexibility of the macromolecular chain is stronger than that of para-aramid, and the fiber crystallization The strength is smaller than that of para-aramid.

3. Performance characteristics of aramid fiber

1. Mechanical properties

The most significant characteristics of para-aramid are high strength and high modulus. Its strength is greater than 25 g/den, which is 5 to 6 times that of high-quality steel, 3 times that of glass fiber, and 2 times that of high-strength nylon industrial yarn; its modulus is It is 2 to 3 times that of high-quality steel or glass fiber, 10 times that of high-strength nylon industrial wire, and its toughness is 2 times that of steel wire. In addition, aramid fiber is light in weight, its weight is only about 1/5 of steel wire.

Comparison of properties between para-aramid and other high-strength fibers

2. Heat resistance

Aramid fiber has excellent thermal stability. Meta-aramid fiber has almost no loss of strength at 130°C. It can be used at 220°C for more than ten years. At 260°C for 100 hours, the mechanical strength still maintains 65% of the original, 400 It begins to carbonize at about ℃ without melting. The heat resistance of para-aramid is better than that of meta-aramid, with a shrinkage rate of 0 at 150°C and no decomposition or melting at a high temperature of 560°C. The strength and modulus of nylon and polyester decrease as the temperature increases.

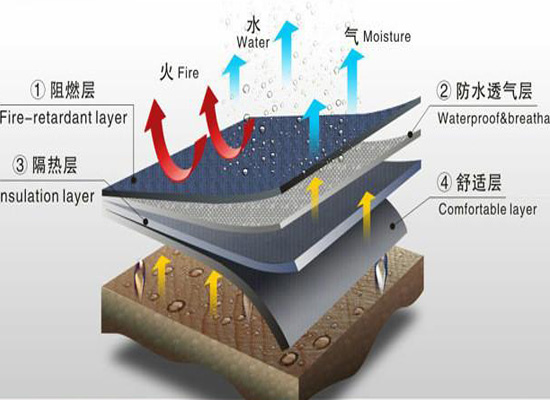

3. Flame retardant performance

Usually the oxygen content in the air is 21%, but the limiting oxygen index of meta-aramid fiber is greater than 28%, and the limiting oxygen index of para-aramid fiber is about 30%. It is a flame-retardant fiber, so it will not burn in the air and will not burn in the air. It supports combustion, has self-extinguishing properties, and does not produce droplets. When encountering extremely high temperatures, the fibers will rapidly expand and carbonize, forming a unique thermal insulation layer that can block external heat from entering the interior and play an effective protective role. This inherent characteristic derived from its own molecular structure makes aramid permanently flame-retardant and has the reputation of “fire-proof fiber”.

4. Chemical corrosion resistance

Aramid fiber has excellent chemical corrosion resistance. Usually, the performance of aramid fiber will be significantly affected only if the aramid fiber is exposed to a relatively high concentration of acid or alkali solution for a long time. Also, aramid is not sensitive to mold or rust.

5. Electrical insulation

The electrical conductivity of aramid fiber is very low, and because the fiber has poor hygroscopicity, it can maintain excellent electrical insulation properties in high and low temperature and high and low humidity environments. The breakdown voltage of insulating paper made of meta-aramid fiber can reach 100kV/mm. The resistance of para-aramid fiber reaches 5×1014Ω/cm. Due to its excellent electrical insulation properties, it has good application prospects in the electronic and electrical fields.

In addition to the properties introduced above, aramid cord also has good aging resistance, wear resistance and radiation resistance. As a type of high-performance material, the excellent properties of aramid fiber have been developed and applied in different fields.

4. Market application of aramid fiber

1. Military and defense fields

Aramid composite materials can be used to manufacture missile solid rocket motor casings, pressure vessels, spacecraft cockpits, submarines, bulletproof armored vehicles, bulletproof cash transport vehicles, bulletproof plates, bulletproof helmets, body armor, etc.

2. Security protection field

The flame-retardant and high-temperature resistance of personal protective equipment is an important condition for ensuring personnel safety. With the development of material science and technology and textile processing technology, flame-retardant protective clothing has been temporarilyThe application of durable flame retardant finishing and semi-durable flame retardant finishing has gradually developed into durable flame retardant finishing and intrinsic flame retardant materials.

3. Rubber reinforcement field

Because rubber has high elasticity and low elastic modulus, it is easily deformed under the action of external force. Therefore, many rubber products must use fiber materials or metal materials as the skeleton. Cord fabrics, cords, yarns, canvas, integral belt cores, straight warp and straight weft fabrics made of aramid are used as skeleton materials for tires, power transmission tapes, material conveying tapes, and hoses.

4. Environmental protection field

Aramid has excellent heat resistance, flame retardancy and chemical stability, and can work in high-temperature and harsh environments for a long time. It is an ideal material for processing high-temperature-resistant filter bags and is used in areas with heavy air pollution such as steel, cement, and carbon black. High temperature smoke and dust filtration.

Non-woven fabrics woven from meta-aramid fibers have very good dust filtering properties. For example, as a high-temperature filter cloth, meta-aramid non-woven fabrics with a density of 380 g/m2 have higher dust filtering properties than polyester cloths of 530 g/m2 and acrylic cloths of 600 g/m2. g/m2 better filtration properties. In the field of bag dust removal, meta-aramid filter bags have a service life of more than two years when the exhaust gas temperature does not exceed 200°C, the humidity is 6%, and the SO2 content is 100ppm.

5. Electronic and electrical materials field

(1) Antenna structural parts

(2) Special printed circuit substrate

(3) Aramid insulating paper

(4) Optical fiber

6. Aerospace field

Aramid can be used to make secondary structural materials for large aircraft, such as cabin doors, windows, wings, fairing surfaces, etc. It can also be used to make interior ceilings, warehouse walls, etc. to reduce their weight.

7. Sports equipment field

Make full use of the properties of aramid such as high temperature resistance and fatigue resistance to make boxing gloves, mountaineering boots, racing car bodies, horse racing helmets, etc. that have harsh sports conditions. It can also be used to make rackets, snowboards, ski poles, sleds, bows and arrows, bow strings, etc. Fishing rods, kite frames, golf clubs, rowing boats, etc.

8. Other fields

(1)Sealing materials

(2) Rope

(3) Friction materials

(4) Building materials