Research progress on multi-layer fire extinguishing protective clothing

Research progress of Multi-layer fire extinguishing protective clothing

Structural composition of fire extinguishing protective clothing

Statistics from the Fire and Rescue Bureau of the Ministry of Emergency Management on the fire and fire situations reported by national fire rescue teams in 2021 show that in 2021, a total of 748,000 fires were reported across the country, with 1,987 deaths, 2,225 injuries, and direct property losses of 6.75 billion yuan. At present, the fire situation in our country is still severe. Fire protective clothing with protective properties can improve the work efficiency of firefighters and ensure their life safety. Fire protective clothing in my country is mainly divided into five categories: fire extinguishing clothing, fire insulation clothing, fire protection clothing, fire command clothing and fire chemical protective clothing. Among them, fire-fighting suits are traditional fire-fighting suits that are flame-retardant, heat-insulating, waterproof and moisture-permeable, effectively ensuring the personal safety of firefighters during firefighting.

(1) Outer layer

GA 10 – 2014 “Firefighter Fire Fighting Protective Clothing” stipulates that fire fighting protective clothing is composed of an outer layer, a waterproof and breathable layer, an insulation layer, and a comfort layer. The outer layer of fire-fighting protective clothing is exposed to the air and directly faces the high temperature of the flame, so the outer layer fabric is required to have good flame retardant properties. When carrying out rescue activities in complex and changeable harsh environments, hooking and friction are inevitable, so the outer fabric must also meet certain physical and mechanical properties.

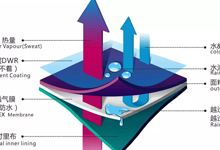

(2) Waterproof and breathable layer

A large amount of water is usually used as a fire extinguishing agent at a fire scene. The environment at the scene is high temperature and humidity. The human body is prone to secrete a large amount of sweat when performing high-intensity activities in this environment. Firefighting protective clothing will absorb a large amount of water, which will not only make the clothing heavier, but also It will also change the original heat transfer method of the clothing. Therefore, the waterproof and breathable layer must first prevent external water from penetrating into the internal insulation layer, and it must also discharge sweat vapor. At present, waterproof and breathable layers mostly use waterproof breathable film + flame retardant base fabric/cotton cloth. The most common waterproof and breathable films include polytetrafluoroethylene (PTFE) film, polyethylene (PE) film, etc. In addition, the waterproof and breathable layer also needs to have a certain resistance to hydrostatic pressure and good thermal stability.

(3) Insulation layer

The fire temperature is generally between 60 and 1 100 ℃, and the thermal protection performance is between 1.5 and 200 kW•s/m2. The thermal protection performance of fire-fighting protective clothing mainly relies on the thermal insulation layer, which can effectively block the harm to the human body caused by heat conduction and thermal radiation. On the one hand, the insulation material needs to isolate the heat conduction of the air to prevent burning injuries to firefighters; on the other hand, it needs to dissipate sweat in time to prevent heat accumulation from causing harm to the human body. The thermal insulation layer generally uses needle-punched nonwoven fabrics or three-dimensional mesh knitted fabrics to reduce heat penetration by adding an air layer with a small thermal conductivity. Commonly used materials are meta-aramid, para-aramid, flame-retardant cotton, etc.

(4) Comfort layer

The innermost lining of fire extinguishing protective clothing is called the comfort layer, which is in direct contact with human skin, so it is required to be flame retardant and also have excellent comfort. This requires it to have good moisture absorption and moisture permeability properties to reduce the feeling of stuffiness, prevent human body dehydration, give firefighters a good sense of wear, and ensure operational efficiency. It is usually sewn together with insulation, often using an aramid/fire-retardant viscose blend woven fabric.

Performance requirements for fire extinguishing protective clothing

(1) Security

Flame retardancy and thermal protection are two major indicators for evaluating the safety performance of fire-fighting protective clothing. Safety performance accounts for about 55% of the protective performance, which is mainly related to the flame-retardant outer layer of fire-fighting protective clothing. Although flame retardancy and thermal protection performance are both indicators for evaluating the safety performance of protective clothing, there is no obvious correspondence between these two properties.

Flame retardancy refers to the ability of fabrics to be flame-resistant or non-combustible when placed in a fire source, and to self-extinguish and stop burning quickly after leaving the fire source. As functional protective clothing, fire-fighting protective clothing must first ensure flame retardant properties. The acquisition of flame retardant properties mainly depends on the outer fabric. The flame retardant properties of the outer fabric can be obtained by treating the fabric with flame retardant finishing agents and weaving with new flame retardant fibers. The former is cheap, but washing will cause the flame retardant to fall off, and the flame retardant effect is not lasting. Therefore, high-performance flame retardant fibers with permanent flame retardancy are commonly used at home and abroad.

Thermal protection refers to the ability of firefighting clothing to protect the human body from thermal hazards in high-temperature and hot environments. The introduction of some new functional materials is an important way to improve the thermal protection performance of firefighting clothing, and it is also one of the development trends of firefighting clothing. Such materials include phase change materials (PCM), shape memory materials (SMM), aerogels, etc.

(2) Comfort

The important role of clothing comfort is reflected in three aspects: thermal and moisture comfort, sports comfort, and tactile comfort. Fire rescuers need to wear fire-fighting helmets, flame-retardant hoods, and fire-fighting equipmentFighting suit, rescue apparatus, explosion-proof lighting headlamp, fire-fighting gloves, safety rope bag, air breathing apparatus, waist axe, safety belt, fire-fighting combat boots and two hoses, these equipment weighed 41 kg. Firefighters need to complete rescue operations under load-bearing and high-speed working conditions. Therefore, fire-fighting protective clothing should fully consider thermal and moisture comfort and sports comfort.

Thermal and moisture comfort includes the thermal comfort and moisture comfort of fabrics, which means that the fabric can transfer heat and moisture well, and you can feel comfortable wearing this garment. At present, most general firefighting suits have a 4-layer structure. The clothing is thick and has excellent protective performance but poor moisture and air permeability. The balance between the body’s metabolic heat and the heat dissipation capacity of the protective clothing is difficult to achieve, which can easily cause heat stress and produce ” “Excessive heat protection” problem seriously affects the safety and health of firefighters. Generally, the thermal and moisture comfort of firefighting suits can be tested by wearing human body tests and warm-body dummy tests. In order to improve the thermal and moisture comfort of fire protection clothing, mathematical models that simulate skin-air layer-fabric-environment heat and moisture transfer are currently used as the carrier for heat transfer and moisture conduction analysis, and structural changes of fabrics and multi-layer fabrics are also used. Composite, it can improve comfort while taking into account the functionality of firefighting suits.

Clothing ergonomics is people-centered and uses clothing as a medium to achieve the best match between people, clothing, and the environment. The sports comfort of clothing reflects the ergonomic performance of clothing from the side, which means that the human body can move freely when wearing clothing of appropriate size. The structural design of fire-fighting protective clothing should fully consider the principles of ergonomics, focusing on the design of collars, shoulders, elbows, arms, cuffs, armpits and other parts, to improve the convenience of putting on and taking off the clothing, and achieve lightweight and flexibility, thereby Reduce the physiological load of firefighters, improve rescue efficiency, and ensure life safety.