Research progress on color construction of high-performance fibers and their products

Research progress on High performance fibers and color construction of their products

Summary

High-performance fibers and their products are key materials for the development of my country’s textile industry, which are related to the development of the national economy and national strategic security. In order to promote the development of high-performance fibers and their products, grasp the frontiers and development trends of their dyeing methods, and break through the industry’s technical bottlenecks, this paper reviews the research progress on the color construction of high-performance fibers and their products at home and abroad. This article focuses on an overview of the technological innovations in color construction of high-performance fibers represented by aramid, carbon fiber, polyimide fiber and ultra-high molecular weight polyethylene fiber, from chemical dyeing such as carrier dyeing, non-aqueous medium solvent dyeing and dope dyeing. This paper summarizes the basic principles and development trends of the color construction of four high-performance fibers in terms of the method and the physical structure chromogenic method, discusses the main challenges encountered in the construction of high-performance fiber colors, and looks forward to the future research directions in this field. . It is pointed out that the color construction of high-performance fibers and their products still needs to be further improved in theoretical research, in order to provide theoretical and application reference for promoting their high-quality development.

High-performance fibers refer to chemical fibers with special physical and chemical structures, properties and uses, or with special functions. Carbon fiber, aramid fiber, polyimide fiber and ultra-high molecular weight polyethylene fiber are the four most widely used high-performance fibers. They are mainly used in aerospace, national defense technology, military engineering, construction industry, transportation, medical protection, Civil industry and electronic communications and other fields. However, with the broadening of the application fields of high-performance fibers, the preparation of colored high-performance fibers poses challenges. Due to the special molecular structure and surface physical and chemical properties of high-performance fibers, such as large inter-polymer chain forces, high fiber crystallinity, and strong chemical inertness on the fiber surface, it is difficult for dye molecules to enter the interior of the fiber or combine with the fiber, resulting in high-performance fibers. The color construction of fibers is difficult and it is difficult to obtain the ideal color depth. In order to break through the technical bottleneck of color construction of high-performance fibers, scholars at home and abroad have conducted a lot of research. Based on the structural characteristics and physical and chemical properties of high-performance fibers, they have innovated the surface modification methods and dyeing processes of high-performance fibers, from fiber raw materials to forming. Processing, surface modification and other aspects give color to high-performance fibers.

This article mainly introduces the research progress of the color construction of four high-performance fibers represented by aramid, carbon fiber, polyimide fiber and ultra-high molecular weight polyethylene fiber, and discusses the development direction of the color construction of the above-mentioned high-performance fibers, with a view to providing Preparing high-performance fibers with rich colors provides a certain reference to meet the needs of fashion and special fields.

1

Main methods of high-performance fiber color construction

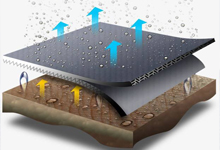

High-performance fibers and their products are key materials for breakthrough development in key areas in the “Made in China 2025” strategic mission. They are also fiber materials that are the focus of development in my country’s textile industry. They are widely used in various fields, as shown in Figure 1. The methods of color construction of high-performance fibers are mainly divided into chemical dyeing methods and physical structure colorimetric methods. Among them, chemical dyeing methods mainly include dope dyeing methods based on fiber manufacturing, carrier dyeing methods optimized for dyeing processes, and non-aqueous medium solvent dyeing methods. Table 1 shows the main methods of color construction of high-performance fibers and their products. 2

Aramid color build

Aramid’s full name is aromatic polyamide fiber, and its industrial products mainly include para-aramid and meta-aramid. Due to its excellent properties such as ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, and stable chemical structure, it is widely used in many fields such as aerospace, military industry, transportation, construction, sports, and electronic appliances. Colored aramid products provide aesthetic and functional flexibility and achieve product identification purposes. In recent years, in view of the molecular structure and dye applicability of aramid, disperse dyes and basic dyes are mainly used for dyeing, and chemical construction methods such as carrier dyeing, non-aqueous medium solvent dyeing, and graft-modified dyeing, as well as structural color physics have been developed. Build method. Among them, carrier dyeing and non-aqueous medium solvent dyeing have received widespread attention.