The development of flame-retardant textile technology in my country

The development of flame retardant textile technology in my country

1. Overview of flame retardant technology

The development of flame retardant technology is accompanied by the development of synthetic polymer materials.

Polymer materials are divided into natural, semi-synthetic and synthetic polymer materials according to their sources. In 1907, Baekeland and his assistants invented phenolic resin, marking the beginning of human application of synthetic polymer materials. Due to their excellent performance and low investment in production applications, synthetic polymer materials have developed rapidly in just a few decades. Industries such as electronic and electrical products, high-rise buildings, aircraft, automobiles, transportation, and decoration have used a large number of natural or synthetic polymers. Polymer materials make polymer materials one of the three important types of materials alongside metals and ceramics.

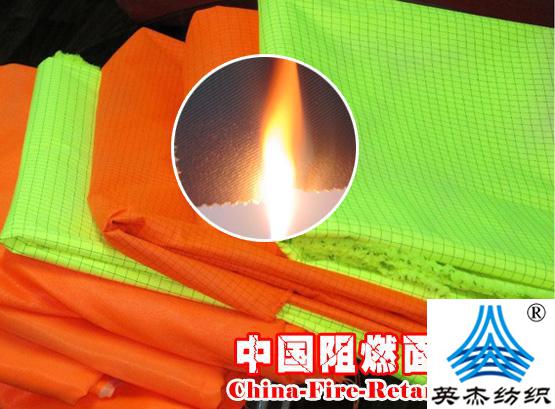

Since polymer materials have the characteristics of large molecular weight and high carbon content, most polymer materials are highly flammable, combustible and combustion toxic, which has also become an important reason for the expansion of losses in the event of fire, thus promoting the Development of flame retardant technology.

The technology of flame retardants has been in use since 1908 when G.A. Engelard and others reacted natural rubber with chlorine to produce flame-retardant chlorinated rubber, pioneering the use of chemical flame-retardant polymers. Especially in the past 40 years, the polymer industry has developed rapidly. In order to meet the needs of development, flame retardant technology has developed rapidly, and many efficient and new flame retardants have been developed.

Flame retardants are additives used to improve the flame resistance of materials, that is, to prevent materials from being ignited and to inhibit the spread of flames. According to the relationship between flame retardants and the flame-retardant substrate, flame retardants can be divided into two categories: additive and reactive. According to the type of flame retardant elements, flame retardants are often divided into halogen series, organic phosphorus series, halogen phosphorus series, nitrogen series, phosphorus magnesium series, inorganic phosphorus-nitrogen series, antimony series, aluminum-magnesium series, inorganic phosphorus series, boron series, Aluminum series, etc.

Flame retardants make flammable polymer materials non-combustible, refractory, self-extinguishing, or slow down the flame propagation speed through the principles of endothermic effect, covering effect, inhibition of chain reactions, and decomposition of non-combustible gases to produce suffocation during the combustion process. The heat release and smoke release rates are reduced, thereby effectively improving fire safety in polymer material applications.

With the continuous development of science and technology and the promotion and application of polymer materials, the research on flame retardant technology has been continuously promoted and in-depth. Its scope of application has covered natural polymer materials such as wood and fabrics, synthetic polymers such as fibers, plastics, and rubber. materials and semi-synthetic polymer materials such as asphalt.

2. Prospects

The use of flame retardant modification technology can effectively improve the fire safety of polymer materials. Therefore, the research and development of flame-retardant modification of polymer materials has potential driving force in promoting social and economic development, improving building safety in public places, and promoting social harmony and stability. The industrialization of flame-retardant products has good market prospects and development potential.

Since traditional halogen flame retardants are particularly prone to producing irritating smoke during the combustion process, some products will also produce toxic carcinogens such as Dioxin (dioxin) during the degradation process, or their incomplete reaction products such as polybrominated biphenyls and polybrominated diphenyl ethers. etc., which pose great hidden dangers to human health and the environment. At the same time, halogen flame retardants release a large amount of hydrogen halide (HX) smoke when flame retardant, which often causes secondary hazards. Therefore, international flame retardant research has been developing in the direction of low smoke, halogen-free, and low toxicity. For example, tri-(tribromophenoxy)-triazine is used as an alternative flame retardant additive for decabromodiphenyl ether and decabromodiphenyl ethane, as well as new flame retardants such as Firemaster550 and ReafasNHP.

With the rapid development of the economy, my country’s flame retardant production and consumption situation continues to develop, with an average annual consumption growth rate of more than 20%. The government and enterprises have realized that flame retardant research has a huge role in promoting society and economy. The flame retardant industry is developing in the direction of environmental protection, low toxicity, high efficiency and multi-functionality. At present, my country has established a professional flame retardant research laboratory and developed nano-halogen-antimony synergistic flame retardants, brominated epoxy resins, magnesium hydroxide flame retardants, high-efficiency flame retardants FR245 and fully biodegradable plastic flame retardants. and other high-efficiency multi-functional composite flame retardants and inorganic environmentally friendly flame retardants.

3. Current status of flame retardant technology in my country

With the development of synthetic technology, my country’s flame retardant technology research has made great progress. Flame retardant products have expanded from pure natural polymer materials to mixed and synthetic polymer materials, and their use scope has expanded from textiles to decoration and building components. , exterior wall insulation, wires and cables, electrical components, road transportation and other fields, many new technologies such as microencapsulation, surface modification, compound synergy, ultrafineness and nanotechnology have emerged, and a series of complete varieties have been developed. New flame retardant with excellent performance. There are more than 16,000 flame retardant-related companies and more than 220 flame retardant scientific research laboratories in China, including related research and development of halogen flame retardants, organophosphate flame retardants, phosphorus-nitrogen flame retardants, and inorganic flame retardants. Rapidly and mass-produced. DOPO, hypophosphite, phosphazene flame retardants, etc.Type � flame retardants have received widespread attention in China, and their related research has made certain progress.

However, there is still a certain gap between domestic flame retardant technology development and international development, mainly as follows:

1. Research started late. Research in this area was only carried out in the 1950s, and it was not until the 1980s that flame retardant technology was developed rapidly, comprehensively and systematically. Due to the lack of joint research and development by universities and manufacturers, the starting point for research on new flame retardants that are energy efficient, non-toxic, non-migrating, high temperature resistant and have good processing properties is still low.

2. Flame retardant standards need to be improved. Our country has initially established a series of national standards for flame retardant products, such as GB20286-2006 National Standard for Flame Retardant Products, the Ministry of Public Security’s “Measures for the Administration of Labeling of Flame Retardant Products”, etc., but these are limited to the combustion performance requirements of the material itself and have not yet been established. Unified national standards for flame retardants. The development, production and consumption structure of flame retardants is unreasonable. There are few varieties of flame retardants, unstable quality and low scientific and technological content. Due to the lack of corresponding legislation and measures, the market for flame retardant products has not been effectively developed.

3. The comprehensive advantages of performance, price and environmental protection are low. An ideal flame retardant can simultaneously meet the requirements of high flame retardant efficiency, low toxicity, good compatibility, high stability, sufficient sources of raw materials, simple manufacturing process, low price, and without excessively deteriorating the processing properties of the flame retardant substrate. and the physical properties and other requirements of the final product. With increasingly stringent environmental regulations, many halogen flame retardants have been severely restricted in the international market due to their high toxicity due to decomposition at high temperatures. Since our country has not yet had clear legislative requirements for this, many new products have been impacted by the low-end market, resulting in high costs and low output, which has dampened research and development enthusiasm, resulting in weak competitiveness in the international market.

4. It is recommended that if my country’s flame retardant development and research wants to keep up with the pace of development, efforts should be made from the following aspects:

1. Strengthen exchanges and cooperation. Flame retardants involve a wide range of industries, and their research, development, production and application require support and cooperation from various industries. Strengthening international exchanges and cooperation can promote us to learn and draw on foreign advanced technology and experience, and shorten the gap between our country and developed countries.

2. Carry out industry-university-research cooperation, develop independent industries, and improve comprehensive competitiveness. Domestic research on the flame retardant mechanism is far from enough. Only by thoroughly studying the mechanism can the development of flame retardants and flame retardant materials be targeted and purposeful, and achieve the goal of “flame retardant design”. The government should promote joint research and development between universities and enterprises, give full play to the talents and equipment advantages of universities and the financial advantages and market advantages of enterprises, and develop new flame retardants that are energy-efficient, non-toxic, non-migrating, high temperature resistant and have good processing properties, and accelerate the development of new flame retardants. Product structure adjustment will promote the increasing rationalization of my country’s flame retardant consumption structure.

3. Improve relevant laws and regulations, gradually improve the standards for flame retardant products and testing methods, further refine the testing and inspection system for flame retardants and flame retardant products, optimize the supervision and certification system, strengthen supervision, and increase the use of flame retardants by enterprises and users. consciousness.

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA