Research and development of PU wet waterproof and breathable coating fabric

Analysis on the Current Situation of Waterproof and Breathable Fabrics at Home and Abroad

1.1 Overview of research and development of waterproof and breathable fabrics

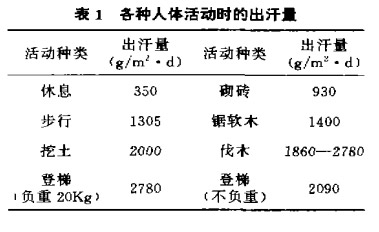

Waterproof and breathable fabrics are unique functional fabrics that the textile industry is constantly developing towards higher levels. They have special functions such as windproof, warm, waterproof, breathable, and water-repellent. In the past few decades. Coated fabrics such as polyethylene, neoprene, and polyurethane have been widely used. Although coated fabric clothing has excellent rainproof and windproof properties and has complete waterproof function, due to the large amount of sweat that cannot be discharged in the form of steam, condensation water is formed inside the clothing, making the human body feel sticky, stuffy and other uncomfortable feelings. Under harsh conditions, it may even freeze and cause frostbite. It cannot adapt to the needs of outdoor activities such as military training and combat, sports mountaineering, skiing and other intense sports. Therefore, the United States, Western Europe, Japan and other economically and military developed countries attach great importance to the research and development of waterproof and breathable fabrics. , have successively developed various waterproof and breathable products, and have been successively applied in military equipment and protective clothing under harsh conditions. Domestic research on waterproof and moisture-permeable fabrics is relatively late and the level is low. So far, most of them are waterproof and impermeable and are low-end products. Waterproofing and moisture-permeable fabrics have become an irreconcilable contradiction, which greatly limits their wearing and use. In 1996, Shandong Keyida Group Company conducted a comprehensive survey and analysis of the current status and development trends of waterproof and breathable fabrics at home and abroad. Based on the national conditions, it was determined in 1997 to research and develop a plan for wet-process polyurethane waterproof and breathable coated fabrics. 10 implementation plans were formulated. We were the first to introduce advanced wet production lines and gained exclusive access to this equipment design technology. In the absence of ready-made information and experience at home and abroad, we organized scientific and technical personnel to explore and form the raw material ratio of the microporous coating through analysis of samples, analysis and demonstration, sample testing, simulated production and other key research stages on the basis of digestion and absorption. , process flow, parameter determination, performance balance adjustment and a series of technical information. Laying the foundation for mass production.

1.2 Types of waterproof and breathable fabrics

In the past few decades, a variety of fabrics that are both breathable and waterproof have emerged, which can be summarized into three types.

1.2.1 High-density fabric

High-count ultra-fine cotton fibers and other ultra-fine synthetic fibers are used to make tight fabrics that undergo heat treatment and chemical treatment to achieve high shrinkage. The fibers are shrunk into a dense tissue, and coupled with a high degree of water-repellent treatment, the fabric is moisture-permeable and waterproof. In principle, when the fabric gets wet, the cotton yarn absorbs and expands, reducing the fiber spacing. This closed-cell mechanism, together with the special waterproofing treatment, prevents water outside the fabric from further penetrating, making it waterproof. High-density fabrics are characterized by good moisture permeability, but low water pressure resistance (generally less than lm), and the fabric density is high. Special spinning processes must be adopted. There are many breakages during weaving, the defective rate is high, and dyeing and finishing are difficult; The fabric has low tearing strength and poor scratch resistance.

1.2.2 Coated fabrics can be divided into two types: hydrophilic coated fabrics and microporous coated fabrics

The surface of the hydrophilic coated fabric is coated with a complete hydrophilic coating, so it is waterproof. However, there are a series of hydrophilic groups in the polymer molecular chain of the coating film that can form weak bonds with water molecules. When the humidity on both sides is not At the same time, these groups will cause water vapor molecules to migrate from the high humidity side to the low humidity side. Moisture permeability is a process of “adsorption, diffusion and desorption”, which improves the moisture permeability of fabrics. Microporous coated fabric is a permanent system of micropores and channels throughout the coating. If the micropore macropore diameter is about 23m or less, then the fabric has waterproof ability, and this microporous structure is also moisture-permeable. Laminated composite fabrics use lamination technology to combine the excellent properties of ordinary textile fabrics and high-tech microporous film products. They learn from each other’s strengths and fully demonstrate the characteristics of the times of differentiation and functionality. They are the main development of waterproof and breathable fabrics at present. Direction In recent years, the Gore-Tex products of the American Gore Company and the Sympatex products of the Dutch AKZO Company have been leading the waterproof and breathable laminated fabric market, and represent the high level of all “waterproof and breathable

1.3 Functions and applications of waterproof and breathable coated fabrics

Waterproof and breathable coated fabric is the first functional product in the international coating industry. It has the special functions of waterproof, breathable, windproof, warm and water-repellent. It can dissipate sweat on the body surface, ensure dry skin, and create a warm interior of clothing. climate. Depending on the versatility of coated fabrics, it can be used in a wide variety of fields:

●Waterproof and breathable: made into rain gear, such as wind and snow raincoats, fishing suits, and sportswear, such as running suits, mountaineering suits, ski suits, military training suits, field combat suits, etc.

·Windproof and warm-keeping: made into cold-proof clothing and protective clothing under various harsh conditions, such as winter cold-proof clothing, sea-going clothing, oil field work clothing, polar expedition clothing, etc. The PU wet-process waterproof and breathable coated fabric we developed has passed the National Cotton Textile Product Quality Supervision and Inspection Center. Tested by authoritative institutions in Germany and South Korea, the product has reached the advanced level of similar international coating products. At present, the Ministry of Public Security has used this product to make multi-functional police uniforms. It is lightweight and warm, rainproof and windproof, has a wide operating temperature range, and is multi-purpose. It has been well received. Analysis of the waterproof and breathable mechanism of 2Pu microporous coated fabric

2.1 Basic requirements for waterproof and breathable coated fabrics Research shows that waterproof and breathable coated fabrics must beThe bonding strength of the polymer is very effective and can reduce the penetration of resin into the yarns during wet roller coating, making the coating tend to form a film on the surface and improving the smoothness, smoothness and softness of the coating film. However, Processing flow 1 is effective in maximizing moisture permeability without emphasizing peel strength.

3.3 Determination and control of the main process parameters of coated fabrics Process conditions are an important part of executing each process. It has a very important impact on the performance and quality of the product. In the trial production of PU wet waterproof and breathable coated fabrics , the main process parameters are as follows: Front water repellency. Front water repellency is mainly to prevent the stamen effect on the fabric during coating, ensure that the coating film tends to the surface to make it continuous and complete, and make the product soft to the touch. Factors affecting front water repellency: (13) Selection of types of waterproofing agents. For Pu coating processing, organic fluorine waterproofing agents with good initial effects and low cost are generally selected. (2) The concentration of the treatment liquid and the twisting rate of the treatment liquid are determined by processing During the process, the concentration of the treatment solution should not be too high. If it is too high, the adhesion strength of the coated fabric will be low and the durability will be poor; if it is too low, the resin will penetrate into the interior of the fabric more, and the hand will become hard or even glued through. Therefore, more attention should be paid to (3) heat treatment Temperature and time. The temperature of heat treatment must be set according to the melting point temperature of the waterproofing agent, and it takes a certain amount of time to melt the waterproofing agent particles, so it must be strictly controlled. Otherwise, the ideal effect will not be achieved.

3.3.2 Solidification temperature

Generally, if the temperature of the coagulation tank is high, that is, greater than 30C, the DMF extraction speed is fast. On the contrary, the immersion speed of water becomes slower, and the dissolved state of the polymer inside is maintained longer, so the thickness is reduced, the density is increased, and the micropores are It becomes smaller and the moisture permeability decreases. And when the resin concentration is low, the viscosity of the compounding liquid itself is low, which is determined by the temperature of the coagulation tank, and the density does not change much. However, the shape of the single crystal micropores becomes rough due to the high temperature of the solidification tank, so attention must be paid to this.

3.3.3 Composition of solidification tank

During wet processing, water is generally used in the coagulation tank. However, considering the easy recovery of DMF, we use a DMF concentration of 10 to 15% for coagulation.

3.3.4 Temperature and composition of water washing tank

When the coated fabric enters the water sink, 30% of DMF still remains in the resin layer. If it is dried directly in this state, the remaining DMF will dissolve the coating again, which will not only destroy the smoothness of the surface, but also cause permeability. Wet performance deteriorates. Therefore, it is necessary to extract all the remaining DMF in the water washing tank using forced methods (such as repeated squeezing by high-temperature squeeze rollers in water washing), otherwise it will be difficult to obtain a smooth and smooth coating surface. Therefore, the concentration of the post-wash tank must be controlled between 0 and 1. In setting the process parameters, the temperature should be between 4O and 60C, and the temperature should be raised in stages to prevent the temperature difference from being too large, causing the micropores to shrink sharply when heated, affecting the moisture permeability. In addition, the large temperature difference from a lower temperature to a higher temperature also causes the hand feel. One of the bad reasons, so watch the temperature.

3.3.5 Drying temperature

The coated fabric coming out of the water washing tank is dried next. Before drying, the residual amount of DMF must be as small as possible. It is generally required that the retention amount of DMF in the wet adhesive film be controlled below 3, otherwise the resin will dissolve again during drying, destroying the moisture permeability and increasing surface adhesion.

3.6 Post water repellent treatment

The main purpose of the product’s post-water repellent treatment is to make the product have lasting water repellency and correspondingly improve the resistance to hydrostatic pressure. In terms of the type of waterproofing agent, we chose Japan’s fluorocarbon resin waterproof and oil-proof agent. However, fluorocarbon resin is difficult to arrange on fibers, and the water repellency of the coated fabric is not resistant to friction and washing. After testing, we used a media agent and catalyst to connect the fiber and fluorocarbon resin, successfully fixing the water-repellent agent firmly on the fiber, solving the problem of being intolerant to friction and water washing, and the product has durable water-repellency

Conclusion

Waterproof and breathable coated fabrics belong to a series of waterproof coated fabric products. Its outstanding advantages are that it is waterproof and can transmit sultry sweat. It solves the irreconcilable contradiction between waterproofing and moisture permeability. It has the characteristics of moisture permeability, water repellency, softness, plumpness, and high-grade surface that other coating products do not have. Added value. Waterproof and breathable coated fabrics are functional fabrics that are windproof, waterproof, coldproof, heat preservation, breathable, moisture permeable, water-repellent, soft to the touch and other high-end fabrics. In developed countries, it is also the preferred fabric for sportswear, casual wear and special functional clothing. This product fills a gap in my country’s waterproof and breathable mid-to-high-end products and has obvious economic, military and social benefits. sfrwgtrhtyy

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA