Fabric inspection standards

1. Fabric quality inspection specifications:

1. After the fabrics are put into storage, they must be inspected according to the sampling method of each style and color before seasoning in the cutting workshop.

2. The content and standards for fabric inspection are as follows:

2.1 Sampling method:

The inspection standard is based on random inspection of 5% of each batch of incoming materials

2.2 Fabric inspection method:

Use a cloth inspection machine to inspect, and inspect on an inclined platform under 3 to 4 40W fluorescent lamps.

2.3 Acceptable range of width, coating, color fastness and color difference:

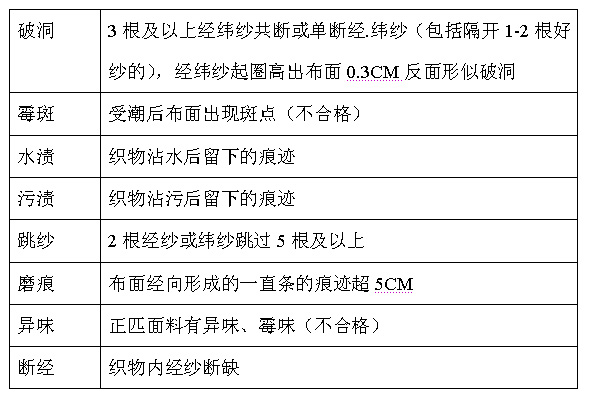

2.4 Defect categories:

2.5 Judgment criteria:

A judgment fabric (piece) standard:

(1) Width, weft bias, color fastness, color difference, coating: If any one inspection item exceeds the acceptable range, the fabric will be judged to be unqualified;

(2) Defect category: If the total number of defects is ≥10 per piece, the piece of fabric will be judged to be unqualified

BJudgment batch fabric standard:

For inspection based on the sampling quantity (pieces) within the batch range; when the number of unqualified items (pieces) exceeds the unqualified judgment number, the batch of fabrics will be judged to be unqualified.

3. All fabrics that have been randomly inspected should be labeled and recorded and reported to the quality inspection department.

4. Acceptable fabrics will be distributed according to relevant procedures.

5. Processing procedures for fabrics beyond the acceptable range:

(1) For customer property, if there is a customer QC following the order in the factory, please ask the QC to sign and confirm on the inspection form and then report it to the production department and quality inspection department. After approval, the materials can be released. Fabrics that have not been confirmed by the customer cannot be shipped.

(2) Non-customer property shall be reported to the Business Department by the Quality Inspection Department for processing according to relevant procedures.

2. Excipient quality inspection specifications:

1. After the excipients are put into the warehouse, they must be inspected according to 3% of the quantity of each style and color before distribution.

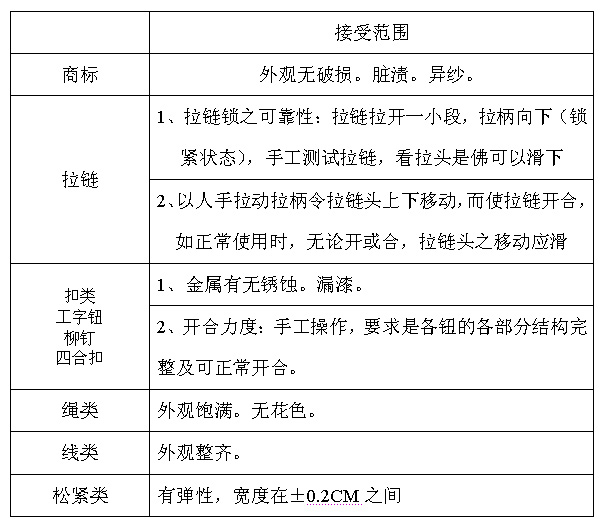

2. The inspection content and acceptance range of excipients are as follows:

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA