Control system (overview)

The water jet loom control system usually uses the CPU as the control center to control the planning, operation, forward rotation, reverse rotation, stop, positioning braking and various fault detection of the loom (mainly including: warp over-tension , left and right hemming, front and rear waste wire, fixed length, weft wire detection, etc.), after analysis and processing, it is controlled through the actuator.

The PLC control system uses the PLC programmable manipulator as the control center, and sends the aforementioned command signals and detection signals to the input end of the PLC. The PLC analyzes and processes the signals and issues execution instructions for control.

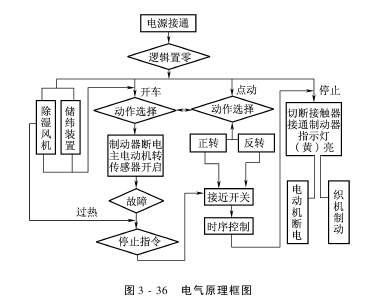

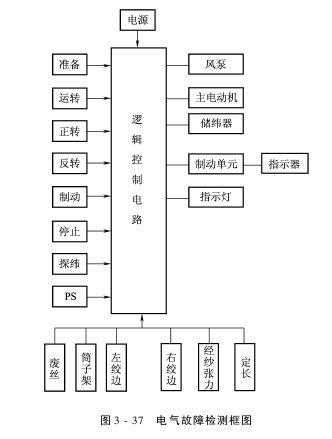

The electrical block diagram of the water-jet loom is shown in Figure 3-36 and Figure 3-37.

The control system mainly includes loom transmission and braking, loom fault detection, weft detection, logic control, electronic weft storage, electronic let-off, electronic take-up and other parts.

The control system mainly includes loom transmission and braking, loom fault detection, weft detection, logic control, electronic weft storage, electronic let-off, electronic take-up and other parts.

AAADFGE465IU8GHYJ

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA