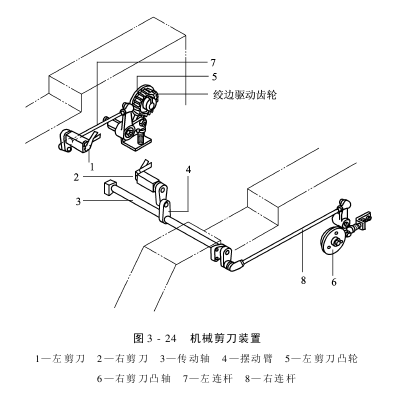

Scissor device

There are three types of scissors for water-jet looms: electric scissors, mechanical scissors and electronic scissors. One set is installed on the left and right sides of the loom. At present, water-jet looms are mainly equipped with mechanical scissors. The scissors on the left side cut off the weft wire after each weft insertion, and the scissors on the right side clamp the CC wire to keep the cast weft wires (usually 4 to 5 wires are retained), and cut off one wire after each weft insertion. Figure 3-24 shows the mechanical scissors device.

Adjustment of scissors

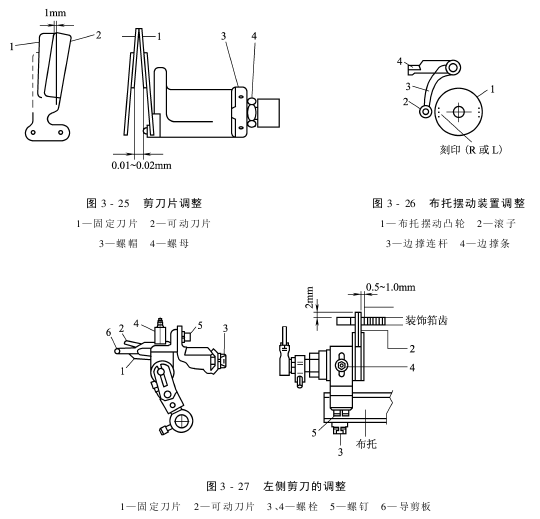

1. Adjustment of scissor blades (Figure 3 -25)

When the scissor blade is replaced with a new one or the ground blade is to be assembled, be sure to adjust the position between the blades.

(1) There should be a 1mm overlap between the blade tips of the fixed blade 1 and the movable blade 2.

(2) There should be a gap between the rear ends of the fixed blade and the movable blade. The degree should be that nut 3 is rotated to a moderate degree and then locked with nut 4. The gap after locking should be 0.01~0102mm. .

2. Adjustment of the Button swing device (Figure 3-26)

Rotate the take-up handle so that the low apex of the Button swing cam 1 (marked part of R or L) and the convex roller 2 are aligned. Adjust the side stays to a horizontal position when the On the inside of the window, the gap between the reed teeth and the movable blade 2 of the scissors is adjusted to the range of 0.5 to 1.0 mm and fixed with bolts 3.

(2) Front and rear positions (Figure 3-27): Adjust with bolt 4.

① Set the position of the hour wheel to 0° (move the reed to the forward position).

② The tip of the scissor blade extends out of the reed 2mm and is fixed with bolt 4.

(3) Guide shear plate (Figure 3-28):

① Adjust the concave part of the guide shear plate 6 to be 0.5mm higher than the top of the fixed blade 1, and temporarily fix it with nut 8.

②Swing the reed 9 to the front so that the groove of the guide shear plate 6 is in the state shown in Figure 3-28, then tighten the nut 8 to fix the guide shear plate 6.

(4) The height of the scissors (Figure 3-27): Use screws 5 to adjust the upper surfaces of each part of the guide shear plate 6 to be consistent with the height of the diameter wire surface.

(5) The relationship between the overlap of the scissor blades and the scissor cam (Figure 3-29):

① Turn the loom by hand to turn the time wheel to the 40° position.

② Loosen the three screws 2 so that the center mark 5 of the scissor cam 1 meets the cam roller 3, and then tighten the three screws 2 to fix the scissor cam.

③The tips of the scissor blades will overlap by 1mm and be adjusted with the scissor connecting rod 4 (the cutting position in this state is about 10°).

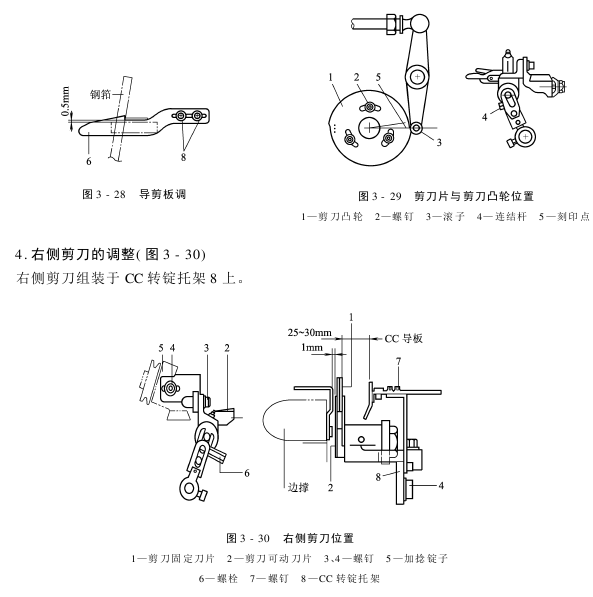

(1) Left and right positions:

①Use screw 3 to tighten The gap between the movable blade and the cloth support is set to 1mm.

②Use screw 7 to set the distance between fixed blade 1 and CC guide plate to 25~30mm.

(2) Front and rear and up and down positions:

① Turn the hour wheel to 0°.

② Use screw 4 to adjust the position of the reed and scissors so that the gap between the reed and the tips of the scissors is 2mm. If the gap is too small, the blade may damage the reed swinging forward.

③ Adjust the tip of the fixed blade 1 by 0.5~1.0mm lower than the warp surface with screw 4.

(3) Overlapping amount of scissor blades:

① Manually turn the loom so that the movable blade and the fixed blade bite deeply.

② Loosen bolt 6 so that the tips of the movable blade and fixed blade overlap by 1 to 1.5 mm, and then tighten bolt 6.

(4) The number of residual weft threads after shearing: Start the loom to introduce the weft thread, and after cutting with the scissors, if the number of residual weft thread threads is too large, it is advisable to slightly increase the amount of overlap at the blade tip. On the contrary, if it is too small, the overlap amount needs to be reduced. The standard number of remaining threads is 4 to 5.

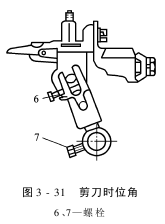

5. Cutting angle (Figure 3-31)

Adjustment of the left scissor cutting angle:

(1) Introduce 1 weft wire into the shed.

(2) Loosen the bolt 6 of the scissors connecting rod, and turn the time wheel by hand to the angle where you want to cut the wire.

The angle when cutting is usually:

Polyester yarn is 15°±5°, Nylon yarn is 10°±5°

Note: Do not loosen the scissor connecting rod when adjusting Bolt 7 (bolt 7 is pressed against the finishing plane of the swing shaft).

(3) When the scissors break, tighten the bolt 6 to fix the movable blade.

(4) Introduce 1 weft thread again, manually rotate the time wheel, and try to cut the thread. It is enough to complete the thread cutting according to the set angle.

AAAMHGCVVBEW

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find information reprinted on this websiteInfringes upon your rights and interests. If there is any infringement, please contact us and we will change or delete it as soon as possible.

AA