Warp let-off mechanism (warp tension adjustment)

For mechanical let-off, the warp tension is set by the weight and position of the weight on the weight arm. The specific steps are as follows:

1. Calculation of the tension on the machine

According to the variety and specifications of the fabric, follow the following Formula to calculate the total tension of the warp:

In the formula: T———— Total warp tension (kg);

K——Tension per denier (g/denier);

Tt——Spinning yarn density (tex);

D1——Warp yarn Denier number;

N——the total number of warp yarns.

Among them, the selection of K value changes according to the type of warp yarn and the finishing method. Generally, the selection can be made by referring to Table 3-2.

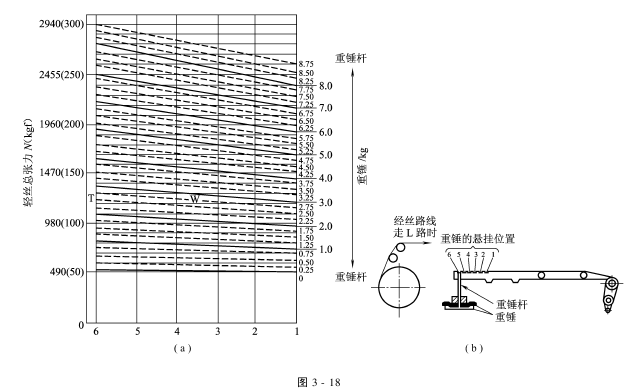

2. Selection of weight position

(1) Calculation of the above formula, warp The total tension is 130kg.

(2) Draw a horizontal line T at the 130kg position in Figure 3-20.

(3) The intersection of T and the weight line of the weight is the weight of the weight 3.25kg.

(4) The intersection of T and the oblique line extends downward to the hanging position of the weight. If it is not an integer, take the closest position.

The relationship between tension and weight shown in Figure 3-18 is only a theoretical calculation value and can only be used as a reference. It should actually be done after the loom is put into operation, depending on its operation conditions.

For electronic let-off, the upper machine tension is pre-set through the operation panel. It is also possible to set relevant parameters so that the warp tension when starting is completely consistent with the tension when parking, and by controlling the position of the cloth mouth, it is possible to prevent the occurrence of parking stalls.

AAAGHRTYJYITLUY

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA