In recent years, my country’s membrane material market has developed rapidly. Membrane materials are widely used in electronics, petrochemicals, food, and medicine. It is widely used in the fields of environmental protection and environmental protection, among which ptfe solar module films are also widely used.

Weld the bus strip to the main grid line on the front side of the battery (negative electrode). The bus strip is a tin-plated copper strip. The welding machine we use can spot-weld the strip on the main grid line in a multi-point manner. The heat source used for welding is an infrared lamp (using the thermal effect of infrared rays). The length of the welding ribbon is approximately twice the side length of the battery. The extra solder ribbon is connected to the back electrode of the subsequent battery piece during back welding.

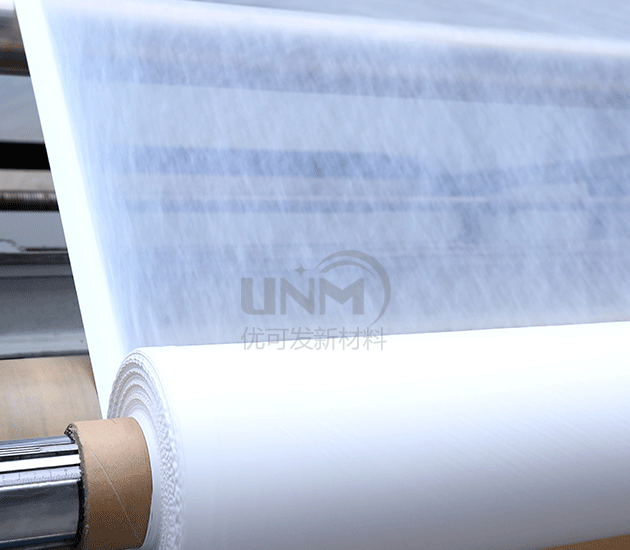

The main feature of ptfe solar module film is surface filtration, which can improve filtration efficiency and improve the problems of increasing filtration pressure and high concentration of fine dust emissions that often occur in traditional filtration methods. It has strong hydrophobicity, low surface energy, and good non-adhesion. It can easily remove dust accumulated on the surface of the material, so it can be rinsed with water to restore its performance, achieve repeated use, and extend its service life.

It is a manufacturer of ptfe solar module thin film environmentally friendly materials that specializes in R&D, production and sales. Our company is different from other manufacturers. Our company can according to the user’s requirements. By optimizing the combination of key technical parameters such as speed ratio, pressure ratio, and operating temperature, the air permeability, thickness, and void ratio can be adjusted online according to the ratio and pore-forming medium to meet your different requirements. Interested parties can enter the store for consultation. </p