PTFE solar module film is a polymer compound made of tetrafluoroethylene and has excellent Excellent properties such as chemical stability and corrosion resistance.

For positive and negative charges, since the positive and negative charges in the PN junction area are separated, an external current field can be generated, and the current flows from the bottom of the crystalline silicon wafer battery to the top of the battery through the load. This is the “photovoltaic effect”. When a load is connected between the upper and lower surfaces of the solar cell, current will flow through the load, and the solar cell generates current; ptfe solar module films are widely used in sealing, electronics, biomedical, textile, environmental protection and other fields. Because of its acid, alkali and corrosion resistance, it can adapt to harsh environments, so its application in environmental protection is particularly prominent. However, polytetrafluoroethylene has low surface energy and poor surface wetting properties, making it unsuitable for bonding, which greatly limits its application. It is widely used in environmental protection, medicine, chemical industry and other aspects.

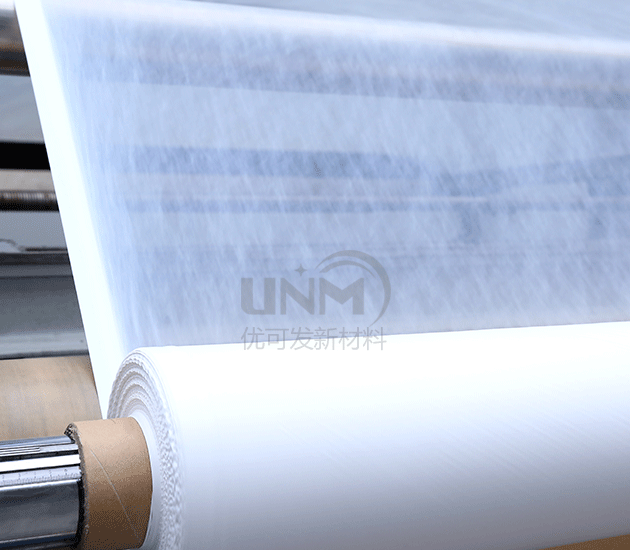

The ptfe solar module film is prepared using a unique biaxial stretching technology, which can ensure the complete retention of bacteria and other impurities while having a large flux. The material is resistant to high temperatures, strong acids and alkali, and has wide chemical applicability. When used for gas filtration, it can achieve 100% retention of various phages, bacteria and particles above 0.02um. PTFE microporous membrane has high filtration efficiency and can meet the filtration efficiency level requirements of sub-high efficiency, high efficiency and ultra high efficiency air filters. Our products are widely used in various fields. You are welcome to come to the company for inspection or enter the store to consult us at any time. </p