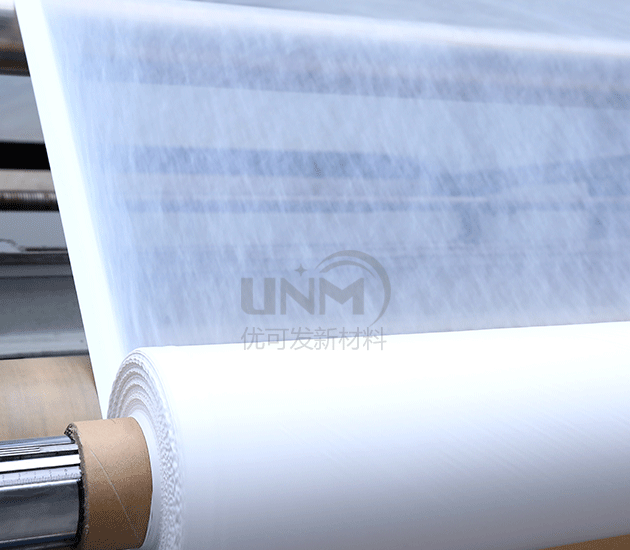

PTFE bubble point membrane composite material is composed of polytetrafluoroethylene microporous membrane and various substrates ( PPS, fiberglass, P84, aramid) are compounded into a new type of material using special composite technology.

In the late 1970s and early 1980s, various filter membrane manufacturers showed their talents and developed their own methods to characterize membranes. However, the method developed by Dr. Tim Leahy of Millipore was adopted by ASTM (American Society for Testing and Materials) in 1983. Therefore, the ASTM F838 standard now widely adopted around the world is based on the contributions of Millipore scientists.

Polytetrafluoroethylene bubble point film, also known as ptfe bubble point film, is generally made of polytetrafluoroethylene (ptfe) suspended powder as raw material, which is expanded and stretched to form a microporous film. . It has a fibrillar microporous structure, the porosity can reach more than 88%, there are 1.4 billion micropores per square centimeter, and the pore diameter ranges from 0.1μm to 0.5μm. Generally, this film is coated on various fabrics and substrates using special processes to become a new filter material.

The polytetrafluoroethylene microporous membrane is prepared using a unique biaxial stretching technology, which can ensure the complete retention of bacteria and other impurities while having a large flux. The material is resistant to high temperatures, strong acids and alkali, and has wide chemical applicability. When used for gas filtration, it can achieve 100% retention of various phages, bacteria and particles above 0.02um. PTFE microporous membrane has high filtration efficiency and can meet the filtration efficiency level requirements of sub-high efficiency, high efficiency and ultra high efficiency air filters. Interested parties can enter the store to inquire and purchase! </p