Humans, as hobby inventors, only have to be familiar with some materials and their special processes, in order to discover the original properties of the materials. On the basis of this, there is the possibility of innovation and the basis for turning it into reality. This is where Teflon microporous membrane comes from.

Consider the filter size and number of filter elements based on the flux provided by the production process. Generally speaking, the flow rate of the filter element (10 inches) is 0.5 tons/hour (the flux of filtered water). For example, if you want to achieve a flux of 1.0T, you can choose a 30-inch filter element, leaving some leeway as appropriate, because As filtration proceeds, impurities accumulate on the surface of the filter membrane, which will cause the flux to decrease. If a 20-inch filter is selected, it may not meet the requirements.

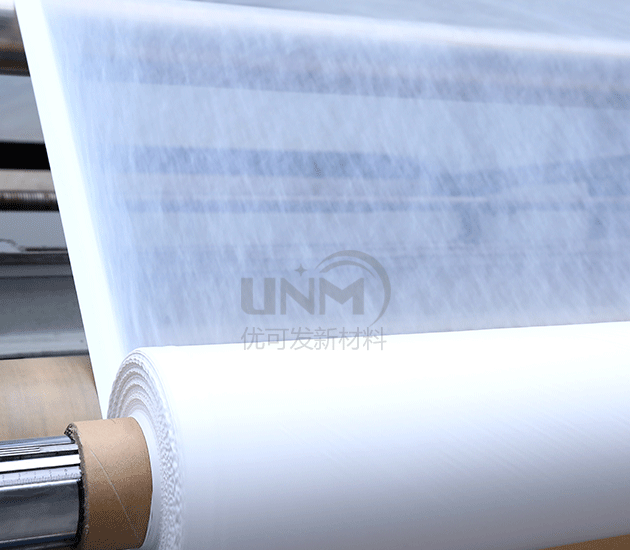

Teflon microporous membrane is made of polytetrafluoroethylene (ptfe) material through special processes such as mixing, extrusion, extrusion, calendering, and biaxial stretching. The porosity of the membrane can reach more than 88% or even higher, and the membrane has 1.4 billion micropores per square centimeter, with a pore diameter ranging from 0.1um to 0.5um, and has high and low temperature resistance (-200℃-200℃) 260℃), no aging, no splitting, no discoloration, and strong weather resistance after long-term use.

The Teflon microporous membranes produced by the manufacturer use imported raw materials, have a full set of advanced production equipment, an advanced clean room and an independent composite slitting workshop, ensuring that the ptfe membrane High-quality production quality; using production and testing instruments imported from the United States to test the quality of PTFE film, and passing international SGS testing and certification, as well as ISI testing and certification. Interested parties can enter the store and contact us. </p