As the saying goes, good experiments depend on good samples, and good samples depend on good samples. Filtration, good filtration depends on choosing the right membrane material. Filtration technology will play an increasingly important role in our experimental work. So what are the filter materials? ptfe hydrophobic membrane is one of them.

Physical adsorption is to realize the hydrophobic modification of nanocellulose through the adsorption of surfactants, quaternary ammonium salts or copolymers by nanocellulose. The physical adsorption method has a simple process flow and can well retain the integrity of nanocellulose. It is a simple and environmentally friendly modification method. However, in the physical adsorption process, the modifier mainly relies on weak binding forces such as van der Waals forces and hydrogen bonds to interact with nanocellulose. Therefore, under the action of a certain external force, the adsorbed hydrophobic substances will fall off, resulting in greater instability.

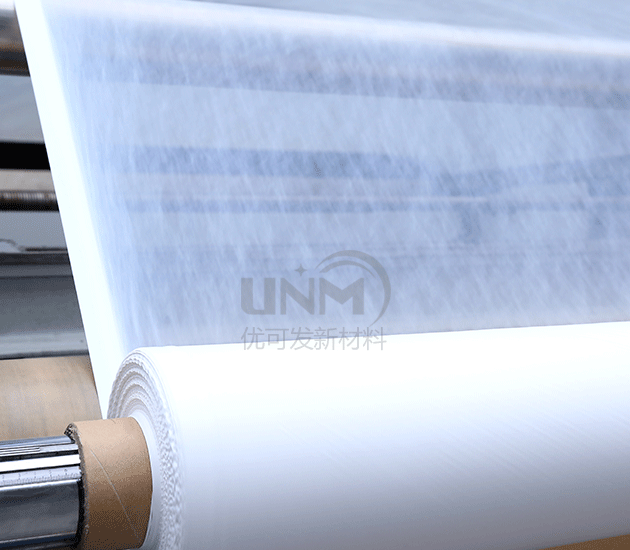

PTFE hydrophobic membrane is prepared using unique biaxial stretching technology, which can ensure complete retention of bacteria and other impurities while having a large flux. It has the characteristics of stable chemical properties, high filtration efficiency, easy dust cleaning, high temperature resistance, and corrosion resistance. Used for liquid filtration to achieve sterility, wide chemical applicability, and high resistance to strong acids, alkalis, and ozone. It is characterized by surface filtration, which can improve filtration efficiency and improve the problems of increasing filtration pressure and high concentration of fine dust emissions that often occur in traditional filtration methods.

It is a fluorine material film manufacturer integrating production, sales and customization. The company has advanced PTFE hydrophobic membrane production lines and composite production lines. The company’s products are widely used in various fields. Interested parties can enter the store for consultation. </p