With the gradual improvement of modern industrial waste gas emission standards, bag dust removal technology has developed rapidly. In particular, the application of PTFE dust collector bags has played a decisive role, which has caused the market supply of PTFE dust removal membrane to show a rapid growth trend. So how much do you know about this material?

Adsorptive dust collector, also known as air filter, is a collection device that allows dust-laden airflow to adsorb dust through filter materials to separate dust and gas. The general adsorption material is activated carbon. This type of dust removal system has a high efficiency in capturing tiny particles. It is very high, but after the activated carbon adsorption is saturated, it needs to be replaced frequently, and the one-time investment cost is very high. The subsequent maintenance cost is also high. It is not suitable for heavy dust environments.

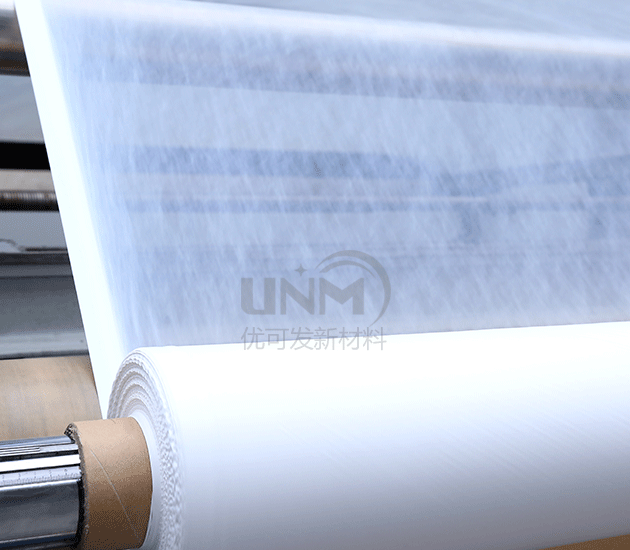

PTFE dust-removing membrane is a microporous membrane made of polytetrafluoroethylene as raw material, using special technology, calendering, extrusion, biaxial stretching and other methods. It has a microporous structure with staggered fibers and a porosity of up to 80%~90%. It has undergone high-temperature heat setting treatment. The microporous structure is stable and can effectively intercept dust particles. Moreover, its pore size is small and uniform, and its surface filtration mechanism makes it easy to Dust removal, strong hydrophobicity, low surface energy, good non-adhesive ability, effectively removes dust accumulated on the surface.

It is a ptfe dust removal film manufacturer specializing in R&D, production and sales. Our company is different from other manufacturers. Our company can according to the user’s requirements. By optimizing the combination of key technical parameters such as speed ratio, pressure ratio, and operating temperature, the air permeability, thickness, and void ratio can be adjusted online according to the ratio and pore-forming medium to meet your different requirements. Interested parties can enter the store for consultation. </p