In recent years, with the improvement of my country’s economic development level, some new products and new technologies have been greatly developed. Good applications, swimming pool filter element support non-woven fabric is one of them.

There are many types of non-woven fabrics. Wide range of applications. Classified from the perspective of production technology, including needle punching, spunlace, thermal bonding, dipping, spunbonding, stitching, meltblown and wet methods. Common raw materials for non-woven fabrics include polypropylene, polyester, nylon, acrylic, ethylene, chlorine, etc. However, the non-woven fabrics currently used for the protective layer of glass fiber filter materials are mainly spun-bonded polyester non-woven fabrics and spun-bonded nylon non-woven fabrics. In China, basically all polyester non-woven fabrics are used. There are polyester non-woven fabrics and nylon non-woven fabrics abroad.

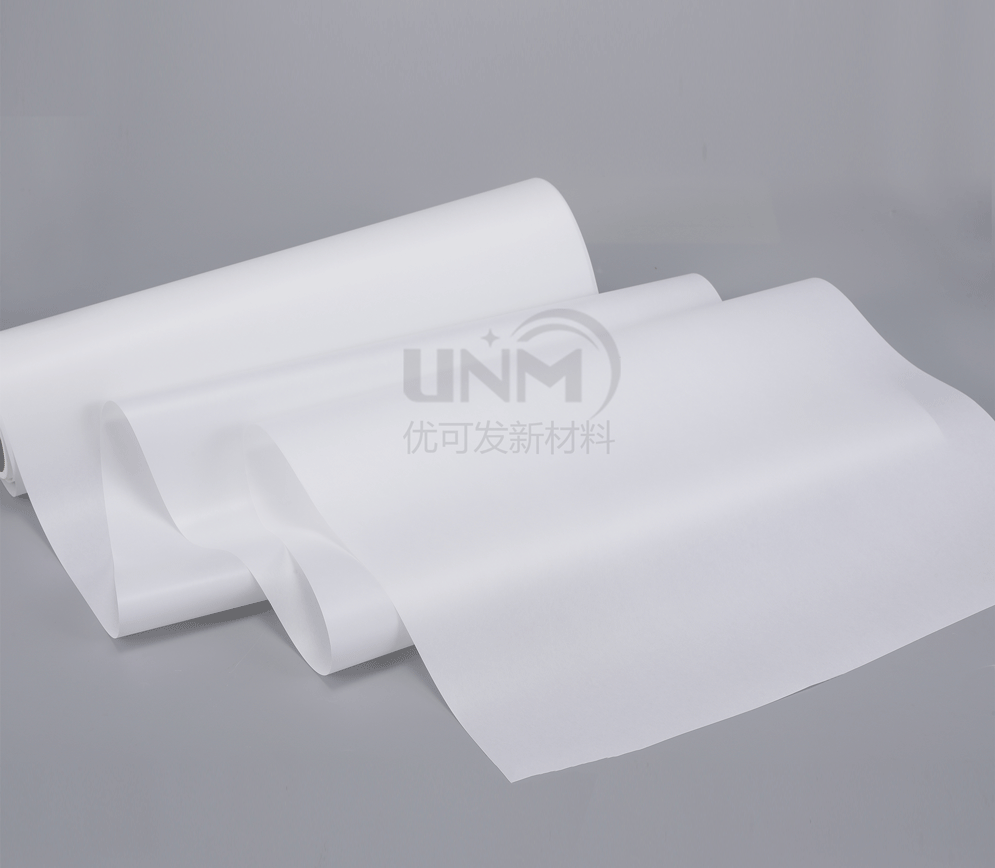

The non-woven fabric supporting the swimming pool filter element is resistant to high temperatures. Because the melting point of polyester is around 260°C. In environments where temperature resistance is required, the stability of the outer dimensions of the non-woven fabric can be maintained. It is also a water-repellent non-woven fabric. The water-repellent properties of non-woven fabrics vary depending on the weight. The larger the weight and thicker the better the water-repellent properties are. If there are water droplets on the surface of the non-woven fabric, the water beads will slide directly from the surface. It can be used in air filtration, medical tape, swimming pool filter elements, seawater desalination front-end treatment, cables, biofilm technology and other fields.

Swimming pool filter element support non-woven fabric for sale can be widely used in air filtration, packaging materials, medical tape, cable wrapping, biofilm and other fields. We have a complete pre-sales, sales and after-sales service system. Interested parties can enter the store to consult us. </p