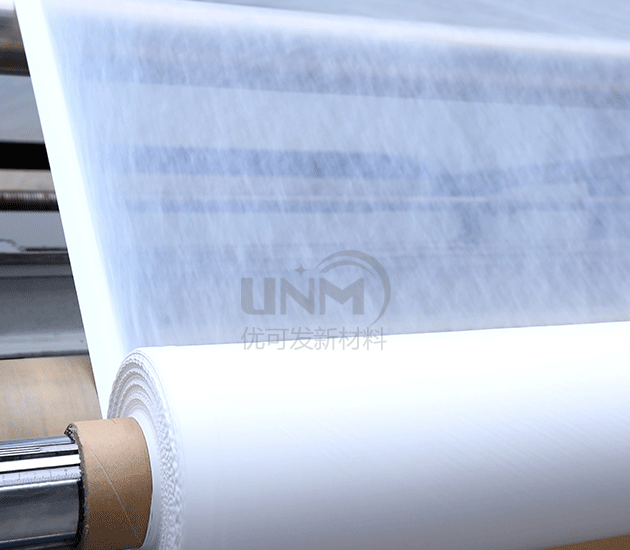

The English name of polytetrafluoroethylene is polytetrafluoro ethylene, or ptfe for short, which is polymerized from tetrafluoroethylene Polytetrafluoroethylene (ptfe) material, commonly known as the “King of Plastics”, is a polymer compound prepared through a biaxial stretching process. It has many derivative products, and ptfe nanomembrane is one of them.

Currently, the filter layer used for masks is mainly polypropylene (PP) melt-blown non-woven fabric, which is composed of fibers accumulated to form a mesh-like through-structure, so it has good filtering properties, barrier properties, heat preservation and adsorption properties. The size of PP melt-blown non-woven fabric fibers on the market is 1-10 μm, which cannot reach the nanometer level. The pores formed by fiber accumulation are large and cannot effectively collect fine particles. The filtration efficiency for particles with a size of 0.3 μm is less than 50%. .

The ptfe nanomembrane is a purely physical barrier and does not rely on static electricity. When the user inhales, the pore size of 100~200 nanometers will pass through the physical screening effect of PM2.5 to PM0.3 and block it in the mask. The surface layer, with the help of the super self-lubricating characteristics of polytetrafluoroethylene material, every time you exhale, it will push the particles attached to the surface of the mask back into the environment. Repeatedly, without relying on electrostatic adsorption, it truly achieves Effective PM2.5 protection effect.

It is a manufacturer of PTFE nano-membrane environmentally friendly materials that specializes in R&D, production and sales. Our company is different from other manufacturers. Our company can according to the user’s requirements. By optimizing the combination of key technical parameters such as speed ratio, pressure ratio, and operating temperature, the air permeability, thickness, and void ratio can be adjusted online according to the ratio and pore-forming medium to meet your different requirements. Interested parties can enter the store for consultation. </p