Data research shows that ptfe nanofilm has excellent chemical stability and is extremely resistant to high and low temperatures. Performance, outstanding non-stickiness, self-lubrication and aging resistance. Highly insulating, flame retardant and superior dielectric properties, it can be said that it has many advantages.

The stretching process of PTFE is a process in which fine fibers are continuously pulled out from the folded lamellae and become longer and thinner. During the uniaxial stretching (longitudinal stretching) process of the PTFE calendered film, the thin fibers are continuously pulled out, forming nodes composed of island nodes composed of unstretched crystal regions and slender fibers connecting the nodes. ——Fiber structure.

The dust layer formed by ptfe nanomembrane filtration is easy to crack and rot, and the filter material has good air permeability. Since the coated filter material relies on a thin film to capture dust particles, the dust layer can only form on the outside of the filter material film. It is hydrophobic, the adhesion between the dust layer and the filter material is small, and it is easy to split. It can fall off by its own weight without external force. If it is blown back, it can be completely removed. If anti-static PTFE high-temperature film is used, the dust will be stripped off more easily and the dust will be cleaned more thoroughly.

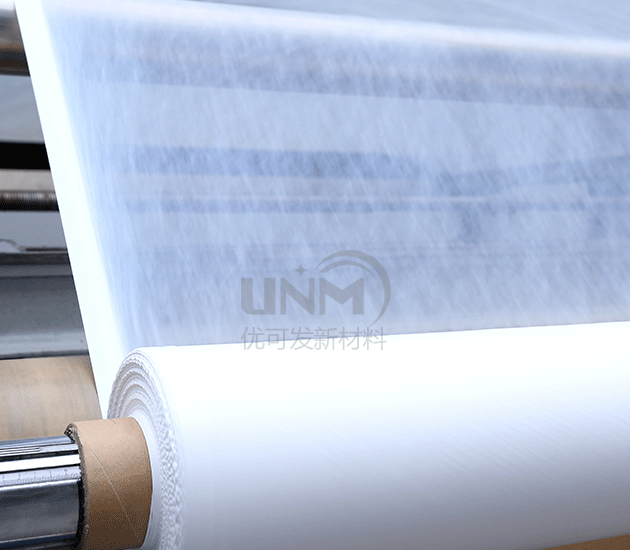

The ptfe nanofilm produced by the manufacturer uses imported raw materials, has a full set of advanced production equipment, an advanced clean room and an independent composite slitting workshop, ensuring the production quality of ptfe film ;Using production and testing instruments imported from the United States to test the quality of PTFE film, and passing international SGS testing and certification, as well as ISI testing and certification. Interested parties can enter the store and contact us. </p