With the rapid development of our country’s economy, people are interested in new materials-polytetrafluoroethylene flat sheets The awareness of membranes is getting higher and higher, and the requirements for the safety, economy and usability of this material are also getting higher and higher.

Compared with hollow fiber membrane bioreactors, flat plate membrane bioreactors can maintain stable operation with high flux (flux is the water production of the membrane) at higher activated sludge concentrations, which is very important for pretreatment. Less demanding. In actual use, although there are grilles, hair removal machines and other equipment in the pretreatment facilities, it is inevitable that some objects such as hair will enter the aeration tank.

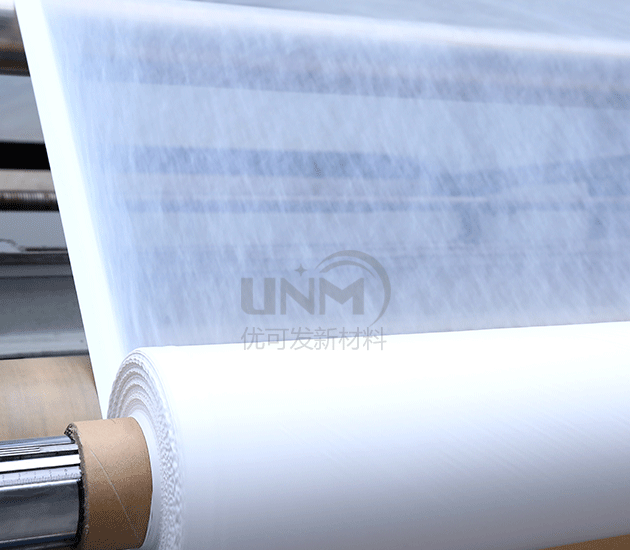

Polytetrafluoroethylene flat film refers to a microporous film made of polytetrafluoroethylene as raw material, using special processing technology, calendering, extrusion, biaxial stretching and other methods. This kind of membrane has excellent breathability, corrosion resistance, aging resistance, high temperature resistance and other properties. According to the usage requirements, the pore diameter can be between 0.1-10um, the thickness can be between 2-100um, and the porosity can reach 50%–80%.

The polytetrafluoroethylene flat membrane produced has strong hydrophobicity, chemical resistance, waterproofness and low wind resistance, and can obtain high dust removal efficiency. For some diameters of 0.1um-0.3 um extremely small particles, the filtration level can reach H13-U16. In addition, the biaxially stretched film can undoubtedly achieve ultra-low emissions in intercepting various types of dust generated during the company’s production process, and it fully complies with current environmental protection standards. Interested parties can enter the store to inquire and purchase! </p