Did you know? The polytetrafluoroethylene bubble-point membrane prepared using unique biaxial stretching technology can ensure the complete interception of bacteria, particles, microorganisms and impurities, and can fully meet people’s requirements in production and manufacturing. At the same time, the membrane also has a large permeability quantity.

Integrity is a physical test. During the filtration process, the porosity of the filter membrane changes due to the capture of a large number of particles and the blockage of large pores, which may “positively” affect the use after filtration. The integrity test values performed by the diffusion flow and bubble point methods, ie, “favored” the integrity test values, causing the drug manufacturer to conclude that filter defects were masked.

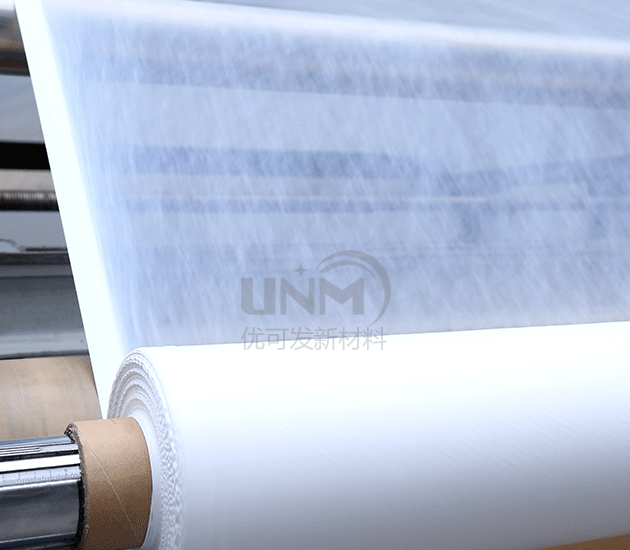

PTFE bubble-point membrane is a microporous membrane prepared from polytetrafluoroethylene suspended powder using unique biaxial stretching technology. This membrane can ensure the complete retention of impurities such as bacteria. , and has a larger flux. When the membrane pore size is smaller and the distribution is more uniform, the bubble point value of the membrane is higher and the retention effect is better. Products are widely used in filtration in medicine, food, bioengineering and other industries.

PTFE film manufacturer specializes in the production of polytetrafluoroethylene bubble point film. It has a full set of advanced production equipment and technology, and also has an advanced clean room and an independent composite slitting workshop to ensure the production of PTFE film. Quality; the products produced are made of imported raw materials, with high uniformity, stable performance, good air permeability, and a filtration efficiency of up to 99.999995%! It can basically meet the filtration efficiency grade requirements of sub-high efficiency, high efficiency and ultra high efficiency filters. Interested parties can enter the store to inquire and purchase! </p