eptfe proton exchange membrane is an indispensable core component material of the fuel cell. It plays an important role in the overall performance of the fuel cell. Performance and service life play a vital role, let’s take a look at it below.

The most widely used PEM on the market is Dupont’s Nafion membrane. Compared with other proton exchange membranes, Nafion membranes have higher chemical stability and higher mechanical strength, and can maintain high conductivity in high-humidity working environments. Currently commercialized perfluorosulfonate PEMs are almost all based on the Nafion structure. However, membrane materials have high requirements on temperature and water content (the proton conductivity drops seriously at medium and high temperatures). When used in direct methanol fuel cells, the permeability of methanol is high and the preparation process is difficult.

The eptfe proton exchange membrane is located in the center of the membrane electrode and is the core component of the proton exchange membrane fuel cell. It plays the role of separating fuel and oxidant, conducting protons and insulating electrons. The performance and life of the proton exchange membrane are directly Determines battery performance and life. Because increasing the battery operating temperature can not only speed up the electrocatalytic oxidation of methanol, reduce the penetration of methanol, reduce poisoning of precious metal catalysts, and simplify water management.

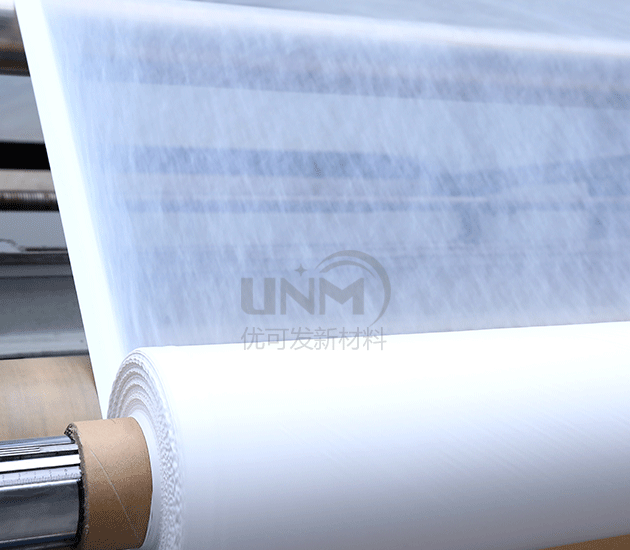

The eptfe proton exchange membrane produced has strong hydrophobicity, chemical resistance, waterproofness and low wind resistance, and can achieve high dust removal efficiency. For some 0.1um-0.3um diameter For extremely fine particles, the filtration level can reach H13-U16. In addition, the biaxially stretched film can undoubtedly achieve ultra-low emissions in intercepting various types of dust generated during the company’s production process, and it fully complies with current environmental protection standards. Interested parties can enter the store to inquire and purchase! </p