Nowadays, with the rapid development of economy, urban air and water pollution are becoming increasingly serious, and industrial hazards The amount of waste and urban garbage is increasing day by day, and urban smog weather also occurs frequently. In order to better protect our home and environment, people have developed ptfe high-efficiency and low-resistance filter materials.

The dielectric constant of polytetrafluoroethylene is relatively small, so it can be used to prepare enameled wires for use in micromotors. In addition, the fluorine plastic film has certain selective permeability to various gases, so this feature can be used to prepare oxygen sensors. In addition, combined with the characteristics of fluoroplastics that cause polar charge deviation under certain conditions, it can be used to prepare speakers, equipment parts, etc.

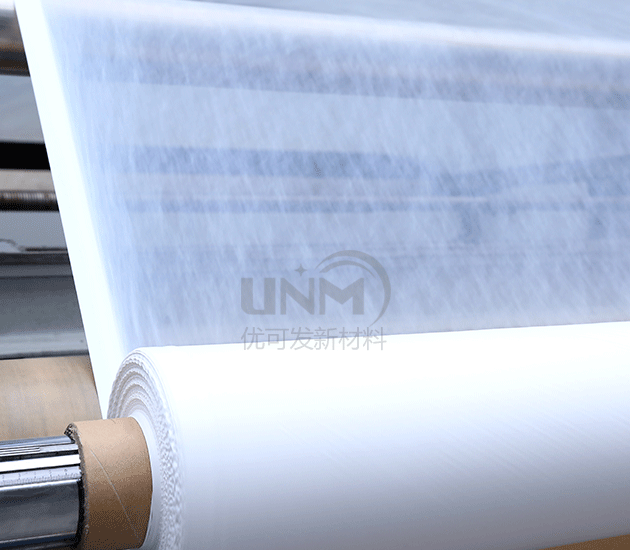

PTFE high-efficiency low-resistance filter material is made by extruding and stretching polymers to form continuous filaments. The filaments are then laid into a network, and the fiber network is then self-bonded, thermally bonded, and chemically bonded. Or mechanical reinforcement method to turn the fiber web into non-woven fabric. It has good high temperature resistance, good low temperature resistance (polypropylene can be used in an environment of 150℃ for a long time, polyester can be used in an environment of 260℃ for a long time), aging resistance, UV resistance, high elongation, good stability and breathability, and Corrosion-proof, sound-insulating, moth-proof and non-toxic.

It is a high-tech enterprise focusing on the research and development, production and sales of ptfe high-efficiency and low-resistance filter materials. It has a factory area of nearly 8,000 square meters and professional production equipment. We have a full set of advanced Production equipment and testing instruments, and a complete pre-sales, sales and after-sales service system. If you are interested, please visit the store for consultation. </p