Nowadays, the rapid development of the filtration industry has brought great benefits to ptfe high-efficiency and low-resistance filter materials. The development prospects and space have caused the market demand for this material to continue to rise, and the future market space will also be broader. Today we will learn about this material.

PTFE material has been widely used in many industries such as petroleum and textiles due to its outstanding corrosion resistance. Representative examples include exhaust pipes, steam pipes, high, medium and low pressure pipes, valves, etc. Especially under relatively harsh environmental conditions such as low temperature and anti-sticking where conventional materials cannot be used, the advantages of PTFE are even more evident.

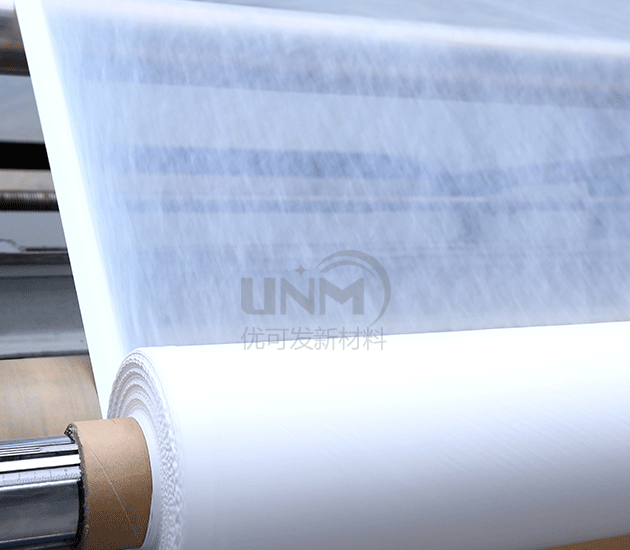

PTFE high-efficiency low-resistance filter material is a high-tech product. Its microporous structure is obtained by mechanical stretching under special conditions without changing its original characteristics at all. Microporous filter membrane The pore size can be controlled at 0.2~0.3μm, and the filtration method belongs to membrane surface filtration. The membrane surface is smooth and has excellent chemical stability, and can resist corrosion, acid and alkali. It does not age and is water repellent.

PTFE high-efficiency low-resistance filter material is prepared using unique biaxial stretching technology, which can ensure complete retention of bacteria and other impurities while having a large flux. The material is resistant to high temperatures, strong acids and alkali, and has wide chemical applicability. When used for gas filtration, it can achieve 100% retention of various phages, bacteria and particles above 0.02um. PTFE microporous membrane has high filtration efficiency and can meet the filtration efficiency level requirements of sub-high efficiency, high efficiency and ultra high efficiency air filters. Interested parties can enter the store to inquire and purchase! </p