The products made of ptfe black base tape membrane have high filtration efficiency, which can reach more than 99%, close to Zero emissions, low operating resistance, fast filtration speed, long service life, and can be reused, thereby reducing operating costs.

No matter what kind of waterproof and breathable membrane it is, it will have a certain degree of water absorption. Because the water vapor inside the structure will condense on the waterproof and breathable membrane when it encounters external cold air when it is discharged from the waterproof and breathable membrane. The porosity of the membrane itself also means that the waterproof and breathable membrane will have a certain degree of water content. If the water cannot be discharged in time, This can cause serious damp problems, especially on the shady sides of the house.

PTFE black base tape film is a polymer compound of tetrafluoroethylene. It is one of the materials with the best corrosion resistance in the world. Except for a few chemicals such as chlorine trifluoride and liquid chlorine, it can withstand other chemicals. All chemical reactions are insoluble in strong acids, strong bases, and organic solutions, and do not change in boiling nitrohydrochloric acid. The temperature resistance range is -195℃~250℃, and the long-term use temperature is -100℃~250℃. The filtration level can reach H13-U16. Widely used in air purification, industrial dust removal, pharmaceutical field, electronic field, clothing field, etc.

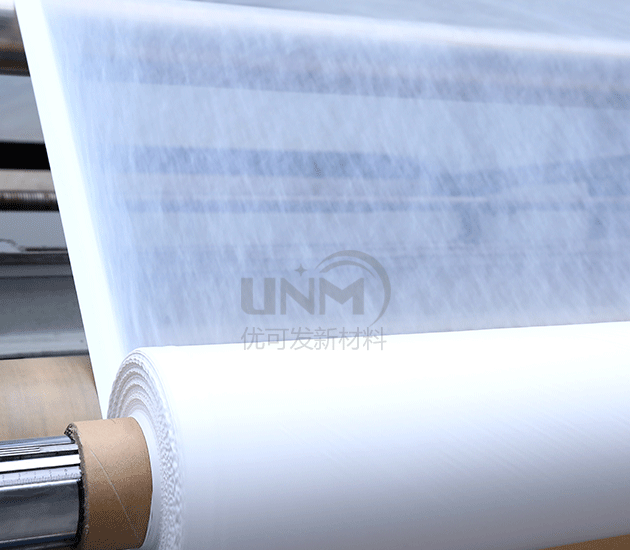

The ptfe black base tape film produced by the manufacturer uses imported raw materials, has a full set of advanced production equipment, an advanced clean room and an independent composite slitting workshop to ensure the production of ptfe film Quality; using production and testing instruments imported from the United States to test the quality of PTFE film, it has also passed international SGS testing and certification, and ISI testing and certification. Interested parties can enter the store and contact us. </p