Do you know which filter material currently has better performance? The answer is obvious, that is ptfe filter material. Today I would like to introduce to you a manufacturer that specializes in producing this material. It is the eptfe film manufacturer. Let us learn more about it in detail.

The surface morphology of the ePTFE microporous film has a spider web-like microporous structure. Pores are formed between the microfibers, and the arrangement direction of the microfibers is basically parallel to the stretching direction; the junction of the fiber bundles is the node, which is formed by the entanglement of many microfibers.

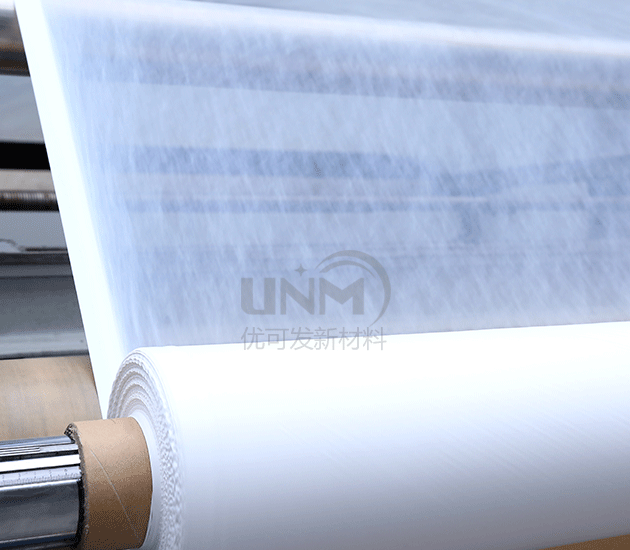

Eptfe membrane manufacturerThe product is prepared using unique biaxial stretching technology, which can ensure the complete retention of bacteria and other impurities while having a large flux. The material is resistant to high temperatures, strong acids and alkali, and has wide chemical applicability. When used for gas filtration, it can achieve 100% retention of various phages, bacteria and particles above 0.02um. PTFE microporous membrane has high filtration efficiency and can meet the filtration efficiency level requirements of sub-high efficiency, high efficiency and ultra high efficiency air filters.

It is a eptfe membrane manufacturer that focuses on the research and development, production and sales of polytetrafluoroethylene microporous membranes. It has a factory area of nearly 8,000 square meters and professional production The equipment is large-scale and is a partner of Fortune 500 companies in the United States; the products we produce are all produced from imported raw materials, with finer molecular weight, cleaner quality, and better uniformity. Moreover, we have a full set of advanced production equipment and testing instruments, as well as a complete pre-sales, sales and after-sales service system. If you are interested, please enter the store for consultation.

</p