Today I would like to introduce to you a new type of filter material, which is polytetrafluoroethylene filter paper. Let’s take a closer look at this material.

The most commonly used chemical analysis filter paper in chemical experiment classes in schools or chemical analysis in factories is divided into two types: one is called qualitative filter paper, and the other is called quantitative filter paper. The quantitative value of qualitative filter paper is 80g/m2, and it is divided into three types according to the filtration speed: fast (no more than 30s per 100ml filtered), medium speed (no more than 60s per 100ml filtered), and slow speed (no more than 60s per 100ml filtered). Not more than 120s).

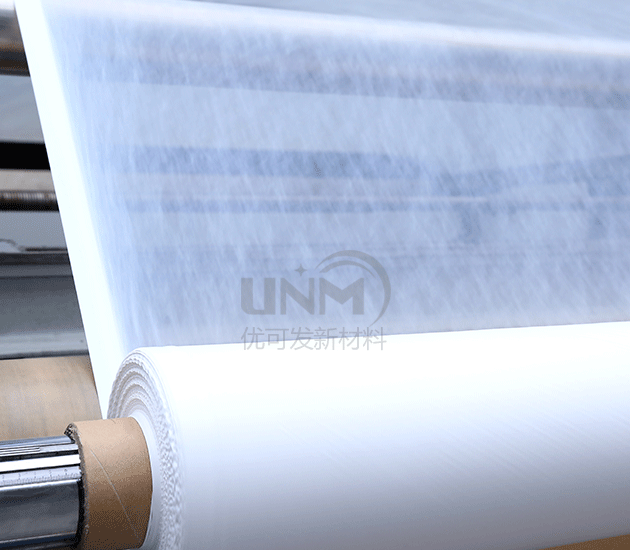

Polytetrafluoroethylene filter paper has a fibrillar microporous structure, with a porosity of more than 85%. There are 1.4 billion micropores per square centimeter, and the pore diameter ranges from 0.02um to 1.5 um, the filtration accuracy can reach U15~U17 level, which can capture most dust particles so that dust cannot enter the membrane through the surface of the membrane. The unique three-dimensional mesh structure prevents dust from passing through. This filtration method is called surface filtration.

It is a polytetrafluoroethylene filter paper manufacturer that integrates production, sales and customization. The company has advanced PTFE film production lines and composite production lines. The company’s products are widely used in various fields. With strong technical force and strict management system, the company ensures that everything focuses on the interests of users and provides users with high-tech, high-quality, high-performance, and high-level products. Interested parties can enter the store for consultation.

</p