At present, new energy has become a strategic development area that the country attaches great importance to. Major enterprises and universities are increasing their efforts to carry out technical research. With the manpower With the investment of resources and resources, it is foreseeable that fuel cell-related industries will explode in the near future, including materials such as polytetrafluoroethylene proton membrane.

Perfluorinated In terms of production technology for sulfonic acid proton exchange membranes, the current mainstream processing methods of perfluorosulfonic acid PEM include hot melt extrusion film forming method and solution casting film forming method. Although perfluorosulfonate PEM is currently the most widely used, it still has the disadvantages of higher cost, poor dimensional stability, and increased temperature that reduces proton conductivity.

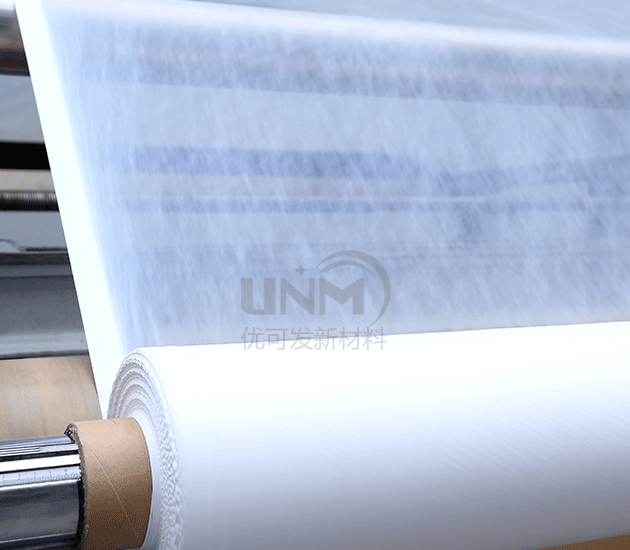

Polytetrafluoroethylene proton membrane is an excellent polymer material that is resistant to high temperature, corrosion resistance, excellent dielectric properties, stable chemical properties and good mechanical properties. Therefore, the material is It is widely used in all aspects of engineering, military and life. However, polytetrafluoroethylene polymer is non-polar and its surface free energy is very low, which makes its surface wetting and hydrophilic properties very poor, which affects its wide application in actual production.

It is a polytetrafluoroethylene proton membrane manufacturer that integrates production, sales and customization. The company has advanced PTFE film production lines and composite production lines. The company’s products are widely used in various fields. With strong technical force and strict management system, the company ensures that everything focuses on the interests of users and provides users with high-tech, high-quality, high-performance, and high-level products. Interested parties can enter the store for consultation.

</p