Did you know that the biaxial stretching process of Teflon electronic film gives the film good void characteristics. Films in different directions are stretched After stretching, the structure of the film’s micropores and agglomerates has changed, and at the same time, the mechanical properties of the film have anisotropic characteristics. Let’s learn more about it in detail.

PTFE resin is one of the polymer materials with the lowest dielectric constant discovered so far, and the integrity of signal transmission in it is better than other materials. It has been used in 5G-related radio frequency antennas, high-frequency copper clad laminates, radar antennas, etc., and can also be widely used in various connectors in the 5G field.

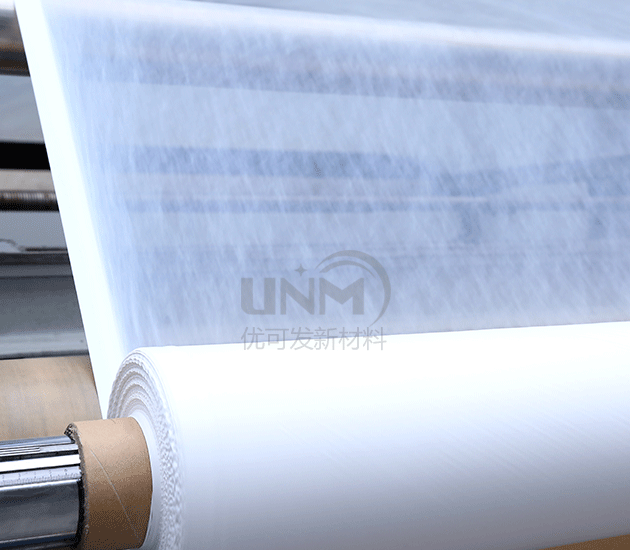

Teflon electronic membraneThe pore size can be between 0.1-10um, the thickness can be between 2-100um, and the porosity can be up to 50 %–80%, as many as hundreds of millions of micropores per square centimeter. It can effectively isolate water points, and the waterproof grade can reach IPX7 or above. Protect electronic instruments from becoming unusable due to moisture or water. Compared with other breathable filter materials, it has excellent air permeability. It is difficult to form a thick dust layer on the surface of the film, and the dust can be naturally peeled off.

The Teflon electronic film produced by the manufacturer uses imported raw materials and has a full set of advanced production equipment. The advanced clean room and independent composite slitting workshop ensure the production quality of PTFE film; production and testing instruments imported from the United States are used to test the quality of PTFE film, and it has also passed international SGS testing and certification, and ISI testing and certification. Interested parties can enter the store and contact us.

</p