With the development of science and technology in recent years and the variability and diversification of the use environment, the waterproofing and sealing reliability of electronic components are facing increasing challenges. Today we will talk about Waterproof and sound-permeable membrane for phones and watches.

Waterproof connectors are widely used in many scenarios. As the name suggests, waterproof connectors can be applied to water-filled areas. In the environment, the connector can ensure normal use of the internal mechanical and electrical properties of the connector under certain water pressure conditions. The application fields are very wide. In industrial environments, such as LED lighting, urban outdoor lighting projects, lighthouses, cruise ships, aviation, industrial equipment, cables, sprinklers, etc., waterproof connectors are required. It has the following characteristics: good sealing, and the waterproof level can reach the IP68 standard, ensuring that electrical appliances will not be damaged by water ingress. Dust-proof, completely prevent the intrusion of foreign objects, and the amount of dust intrusion will not affect the normal operation of the electrical appliance. Prevent dripping water from intruding, vertical water droplets will not cause harmful effects on electrical appliances. Quick to install and easy to use.

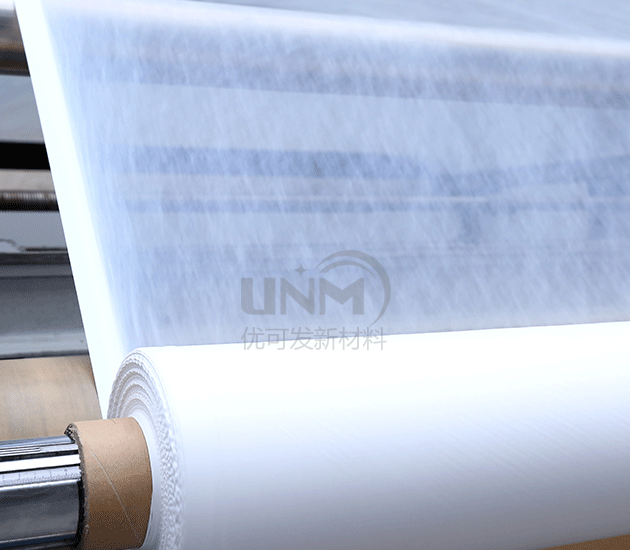

Waterproof sound-permeable membrane for phones and watches can be applied to waterproof connectors for waterproofing, with a protection level of IPX67 or above, and an aperture of 0.1-1 Micron, staggered fibers, high porosity, good waterproof and breathable effect, can meet the waterproof and breathable needs of precision electronic instruments. On the one hand, it maintains the circulation of air, and on the other hand, it prevents electronic components from getting damp. The product has excellent performance and high reliability.

The waterproof sound-permeable membrane for phones and watches produced by the manufacturer uses imported raw materials and has a full set of advanced production equipment. It has an advanced clean room and an independent composite slitting workshop to ensure the production quality of PTFE film; it uses production testing instruments imported from the United States to test the quality of PTFE film, and has passed international SGS testing and certification, as well as ISI testing and certification. Interested parties can enter the store and contact us.

</p