As the concept of green environmental protection slowly takes root in people’s hearts, there is increasing attention to the Teflon microporous membrane manufacturer. At the same time, this manufacturer produces A series of filtration products developed by us are also in constant demand and application.

Microfiltration technology can be divided into pre-filtration and precision filtration, depth filtration, sterilizing filtration, sterile gas filtration, and steam filtration.

Pre-filtration is also called coarse filtration, which screens particles with larger diameters, insect bodies, colloids and suspended solids, etc., to reduce the pressure on the lower precision filtration process. Generally, filter bags, high-flow filter elements and microporous pleated filter elements made of PP material can meet the requirements.

Microfiltration membrane is a porous membrane with a pore size ranging from about 0.01μm to 10.0μm. The filtration principle is mechanical, inertial and diffusion interception, which is similar to the sieving mechanism. , able to intercept all particles, fibers, colloids, bacteria, insects and suspended solids that are larger than the mesh. During the water preparation process, microfiltration technology can remove bacteria and solid impurities, and can be used for the production of mineral water for beverages; the filtration of beer, rice wine, fruit wine and other alcoholic beverages to remove yeast, mold and other microorganisms to clarify the product. And extend the storage period; the milk uses tangential flow technology to retain more nutrients and extend the product life; CIP and bottle washing systems are used to filter out impurities to protect the production system.

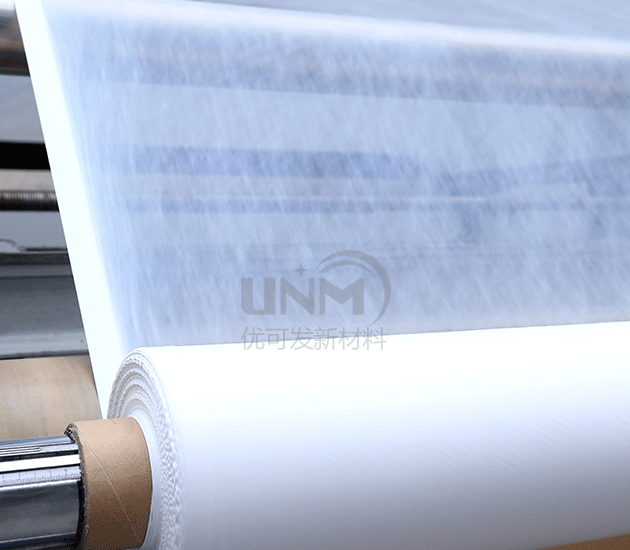

Teflon microporous membrane manufacturer Currently, the independently developed ptfe bubble point membrane is widely used in organic solvent filtration, with There are two categories: hydrophilic and hydrophobic, Teflon microporous membrane manufacturer pore size 0.1 micron-1μm. It can achieve sterility when used for gas filtration, has large flux, is resistant to high temperatures, strong acids and alkalis, and has wide chemical applicability. It is suitable for fermentation tanks, carbon dioxide, nitrogen and compressed air. It can intercept all liquids above 0.02μm. Various phages, bacteria and particles meet the requirements of HIMA bacterial retention experiments. Interested parties can enter the store for consultation and purchase!

</p