Nano membrane fermentation technology is a process technology that uses a special functional membrane as a covering for the aerobic fermentation treatment of livestock and poultry manure. It can be widely used in chicken manure, cattle manure, etc. Harmless treatment and resource utilization of organic waste such as manure, sheep manure, pig manure, straw, urban sludge, kitchen waste, etc. To understand this technology, you must first understandTeflon microporous membrane manufacturercompost nanomembrane.

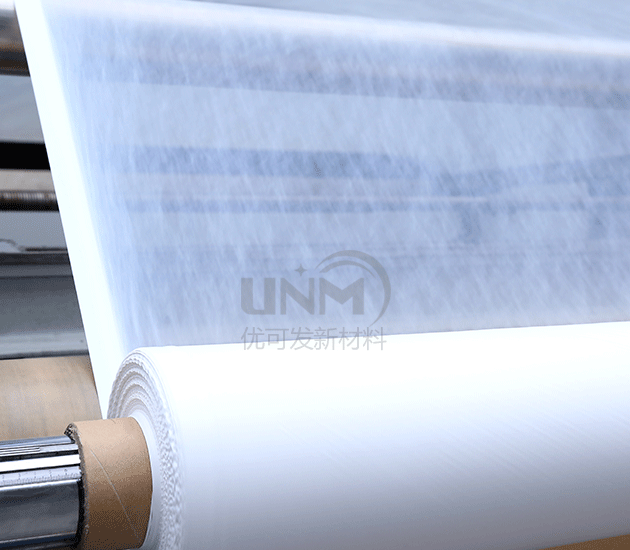

At present, the ePTFE nanocomposting membrane independently developed by Teflon microporous membrane manufacturer is this process technology core materials. The membrane is composed of an ePTFE membrane and a base material. The composite membrane is used to seal livestock and poultry manure in a high-temperature aerobic fermentation pre-fermentation pile. It can protect against wind and rain and avoid the impact of harsh weather, while at the same time allowing the carbon dioxide gas generated during the treatment process to Water vapor is released quickly.

In addition, the ePTFE membrane has a certain insulation and pressurization effect, which can help the system maintain temperature and evenly distribute the oxygen concentration and temperature in the stack, which is beneficial to the entire The stacks have reached temperature conditions that kill pathogens; and the 0.2μm pore size on the ePTFE membrane is an effective physical barrier for dust, aerosols and microorganisms, preventing them from spreading outward.

During the pre-fermentation process, a layer of condensation water film will be generated on the inner surface of the membrane; most odorous substances in the exhaust gas, such as ammonia, sulfur Hydrogen, volatile organic compounds (VOC), etc. will be dissolved in the water film, and then fall back to the pile with water droplets, where they will continue to be decomposed by microorganisms. This covering film can reduce the odor concentration during the fermentation process by 90% -97%, reducing microorganisms in exhaust gas by more than 99%, thus protecting the health of on-site workers and surrounding residents.

During the pre-fermentation process, a layer of condensation water film will be generated on the inner surface of the membrane; most odorous substances in the exhaust gas, such as ammonia, sulfur Hydrogen, volatile organic compounds (VOC), etc. will be dissolved in the water film, and then fall back to the pile with water droplets, where they will continue to be decomposed by microorganisms. This covering film can reduce the odor concentration during the fermentation process by 90% -97%, reducing microorganisms in exhaust gas by more than 99%. Therefore, Teflon microporous membrane manufacturer composting membrane can protect the health of on-site workers and surrounding residents. Interested parties can enter the store for consultation and purchase!

</p