ptfe sewage filtration membrane is also called ptfe bubble point membrane. The name comes from the bubble point test. The bubble point test is a simple and commonly used method to characterize the maximum pore size of a membrane, which is basically the pressure required to blow air through a liquid-filled membrane. Assuming that the membrane is completely wetted by the liquid medium (that is, all pores are filled with liquid medium), the liquid wets the membrane, and at this time all the pores of the membrane are filled with liquid. If air is introduced on one side of the membrane and the pressure gradually increases, the air will not penetrate the membrane due to surface tension at first. When the pressure reaches a certain critical point, the air will overflow from one or more pores. This The critical pressure is called the bubble point.

ptfe sewage filtration membraneBubble point test can be evaluated to a certain extent The pore size of the filter membrane, that is, the larger the membrane pores, the lower the bubble point pressure value. Filter manufacturers generally provide bubble point ranges and minimum acceptable bubble point pressure values for specific pore size filter membranes.

During actual testing, the bubble point pressure value needs to be greater than the recommended minimum value. The key to successful integrity testing is the appropriate wetting fluid and its surface tension. The bubble point is greatly affected by the surface tension of the wetting liquid. If a high-viscosity liquid is used for testing, the bubble point value will be significantly higher than the test value of pure water. The influence of the surface tension of the wetting liquid will decrease as the test temperature increases, because the wetting angle increases and the cosine value also decreases with the hydrophobicity of the membrane. The lower the hydrophilicity of the membrane, the higher the degree of incomplete wetting, which is more pronounced when an aqueous liquid is used as the wetting fluid.

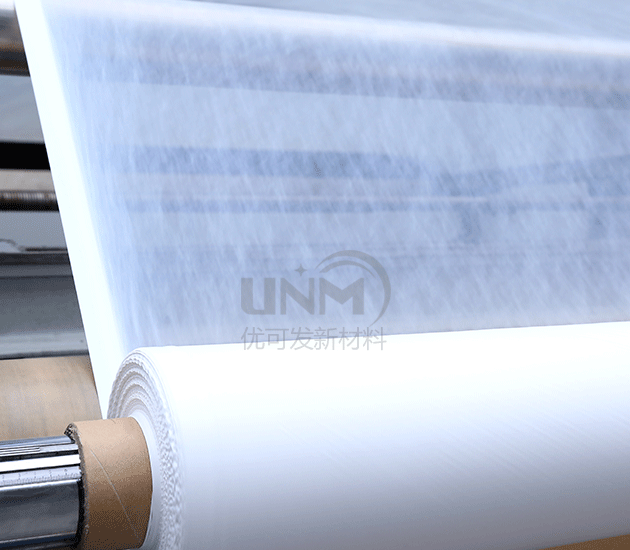

The independently developed ptfe sewage filtration membrane is prepared using a special biaxial stretching process, which can ensure the retention of all small bacteria and other impurities, while having a large flux, the membrane pore size is adjustable, and the pore size range is 0.1-1 micron. It has two categories: hydrophilic and hydrophobic. After integrity testing, it meets the requirements of HIMA retention test. Interested parties can enter the store for consultation and purchase!

</p