In modern society, people pay more attention to their diet, and they pay more attention to the quality of ordinary food and beverages and increase the consumption of fresh food. Meanwhile, another big change is to try to avoid additives and preservatives. Foods that have undergone certain treatments that alter their normal complement of microorganisms are particularly susceptible to environmental microbial attack. For example, kefir, cheese and other dairy products, juices, flavored milk and main dishes. Mushroom growth is also sometimes performed in clean rooms to prevent overgrowth of opportunistic pathogenic spores.

The main function of the clean workshop is to discharge harmful particles in the air through the filter membrane in the purification equipment, and to reduce the indoor temperature and humidity , cleanliness, etc. are controlled within the range required for product production, so the designed room is an important facility to improve product stability and reliability, and an important production process for each enterprise to improve product quality and competitiveness. So, which industries are the current clean workshops used in? Among them, we have to talk about U16 high-efficiency filter material.

The application of clean workshops has provided great help for the processing of many electronic products, and will help prevent the appearance of products from being contaminated after production. Especially in products such as microelectronics, optoelectronics, and electronic materials. Food processing also uses clean workshops, especially the processing of some foods and beverages, and the environment of food clean workshops needs to be controlled to a 100,000-level air purification standard. Only in this way can production needs be met.

The emergence of clean workshops has greatly improved the quality of products in these industries, and has gradually begun to meet people’s daily needs. Clean workshops have also become an important part of some industries. indispensable infrastructure.

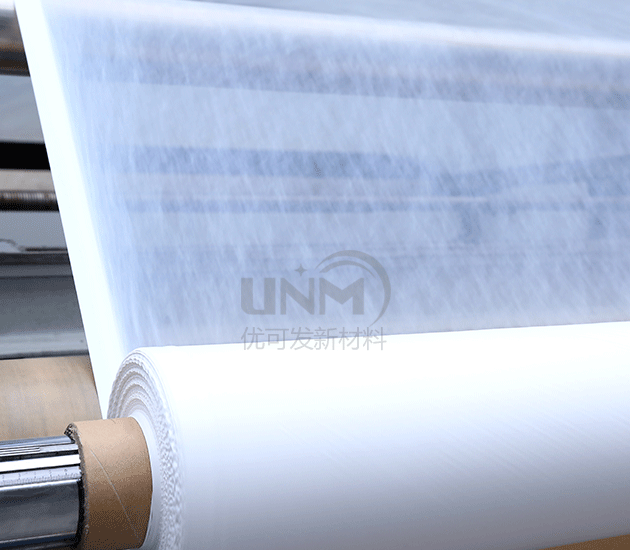

As a high-efficiency separation filter material design solution provider, we are committed to developing and manufacturing high-quality U16 grade high-efficiency filter materials and Filter membranes to protect people, processes and systems. And for air purification filter materials in purification workshops and clean rooms – U16 high-efficiency filter materials, which have low wind resistance and low energy consumption, and are widely used in semiconductors, electronics, flat panel displays, photovoltaics and many other industries. Interested parties can enter the store for consultation and purchase!

</p