Currently, most developed countries use polytetrafluoroethylene. Medical multi-functional protective clothing developed using Teflon clothing membrane as the isolation layer has durable waterproof, water-repellent, antibacterial, antistatic, flame retardant, moisture permeable and other physical and mechanical properties, and is effective against blood, Viruses (liquid or gas heavy) have good barrier properties under both natural and pressure conditions, and the barrier (filtration) efficiency is greater than 99%.

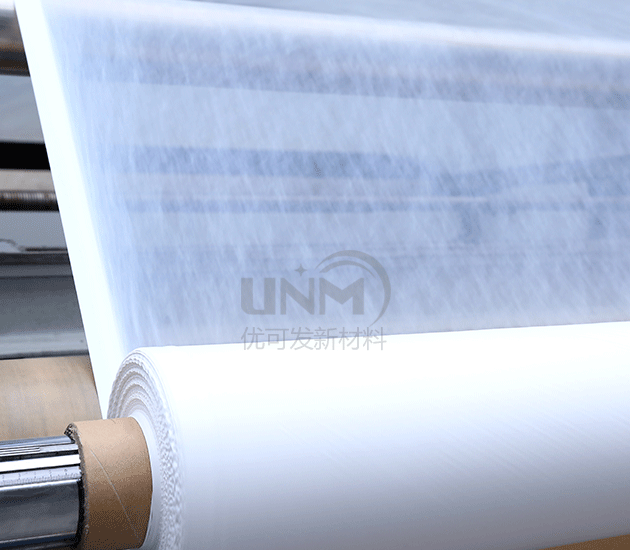

Reusable protective clothing is generally used as daily work clothing and surgical clothing for medical staff. It is mainly made of traditional woven fabrics, high-density fabrics, coated fabrics and laminated fabrics. Since laminated fabrics are made by combining ordinary fabrics with a layer of special film through a lamination process, they have become a mainstream choice in the industry due to their good protective properties and moisture and vapor permeability.

From a consumer and commercial perspective, the difference between good fabrics and ordinary fabrics is not so obvious, and clothes made of ordinary fabrics may even be more expensive than those made of good fabrics. But from the perspective of the traditional luxury goods industry, any non-natural fabrics are unacceptable. So the answer to the question is, unless it is 100% natural fiber fabric, any fabric with chemical fibers is not very good.

Teflon clothing membrane has excellent effect in blocking the penetration of bacterial particles and liquid penetration, and the feel can be changed by changing the composite fabric It has strong tensile strength, good breathability, greatly improved comfort performance, can withstand sterilization, does not contain toxic ingredients, weighs 60~100g/m2, and has good cost performance. Medical products made of it Disposable protective clothing can protect medical personnel from pollution sources, overcome cross-infection, and play an effective protective role.

Teflon clothing film is made of polytetrafluoroethylene as raw material, using special processing technology, after calendering, extrusion, A microporous film made by biaxial stretching and other methods. The product has high filtration efficiency, and Teflon clothing membrane can meet the filtration efficiency level requirements of sub-efficiency, high-efficiency and ultra-high efficiency air filters. Interested parties can enter the store for consultation and purchase!

</p