The difference between domestic waste has always been a topic of concern to many friends. As the name suggests, aerobic composting requires oxygen, while anaerobic composting needs to be carried out in an oxygen-free state. The manufacturer of PTFE aerobic compost membrane will take you through it.

Aerobic composting: Aerobic composting is forced air supply under aerobic ventilation conditions, and uses aerobic microbial activities to Organic fertilizer waste is absorbed, oxidized and decomposed. Thereby realizing the harmlessness and resource utilization of solid waste. In aerobic composting, organic matter is converted into CO2, H2O, NH3, etc., with basically no odor after treatment. Meet environmental protection standards and protect the ecological environment. Aerobic composting requires sufficient oxygen supply and is not too strict on environmental conditions.

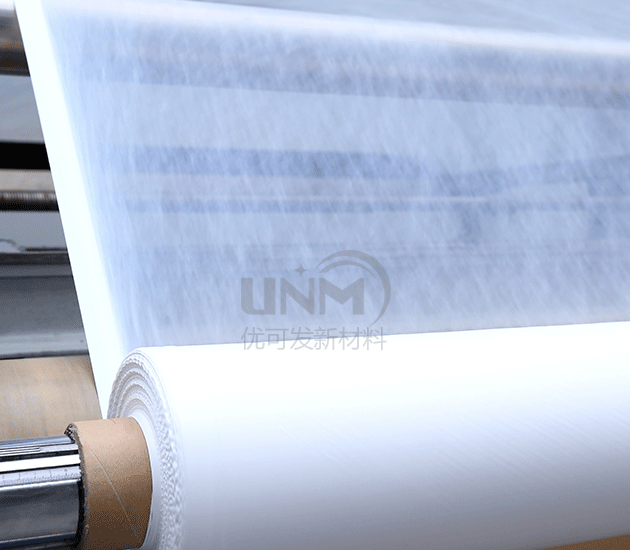

PTFE aerobic composting membrane equipment is composed of nano-membrane fermentation chamber, PLC control system, temperature and oxygen sensors, air supply system, heating system, etc. Among them, nanomembrane is a composite polymer selective permeability membrane produced using nanotechnology. The small pores on the membrane do not allow macromolecules such as odor substances or bioaerosols to pass through. It has waterproof, moisture permeable, bacteria isolation, deodorization, etc. Function. This technology integrates the simplicity of open composting and the environmental protection advantages of closed composting, effectively solving the problems of traditional processes such as large investment, high cost, complex operation, low fermentation efficiency, and high odor and greenhouse gas emissions.

At present, the independently developed PTFE aerobic composting membrane is the core material of aerobic composting technology, with low energy consumption and simple operation. The characteristics of low investment and high quality have been generally recognized by organic fertilizer factories and breeding enterprises.

PTFE aerobic composting membrane technology has always been the core of the business, in biopharmaceuticals, equipment, food and beverages, semiconductor processes, It plays an indispensable role in many fields such as communications, with hole-making capabilities ranging from 0.1μm to 1μm, providing functional solutions such as fine filtration, bacteria and virus removal, waterproofing, breathability, and sound transmission. Interested parties can enter the store for consultation.

</p