Different regions have different customs and customs, but breeding is the most popular industry. In recent years, my country’s breeding industry has developed rapidly in scale and intensification. However, the problem of fecal pollution in the breeding industry has become an important issue restricting the large-scale development of livestock and poultry breeding. How to make breeding production not cause environmental pollution and ecological damage, but also produce high-quality livestock and poultry products, is the key to the sustainable development of modern breeding industry. The essential.

Due to the environmental impact in recent years, many farmers have begun to change careers. But in fact, when it comes to breeding, a big problem is the disposal of feces. PTFE aerobic compost membrane This material is widely used in animal manure treatment.

Aerobic composting technology is generally used to process livestock and poultry manure, crop waste, domestic kitchen waste, etc. under high temperature conditions to ferment and dissolve microorganisms. Aerobic composting is a process in which aerobic bacteria absorb, oxidize and decompose waste under conditions of good ventilation and sufficient oxygen. Aerobic microorganisms oxidize part of the absorbed organic matter into simple inorganic matter through their own life activities, and at the same time release the energy required for microbial growth activities. Manure treated with PTFE aerobic compost membrane can be used as fertilizer, realizing the process of turning waste into treasure and greatly increasing economic benefits.

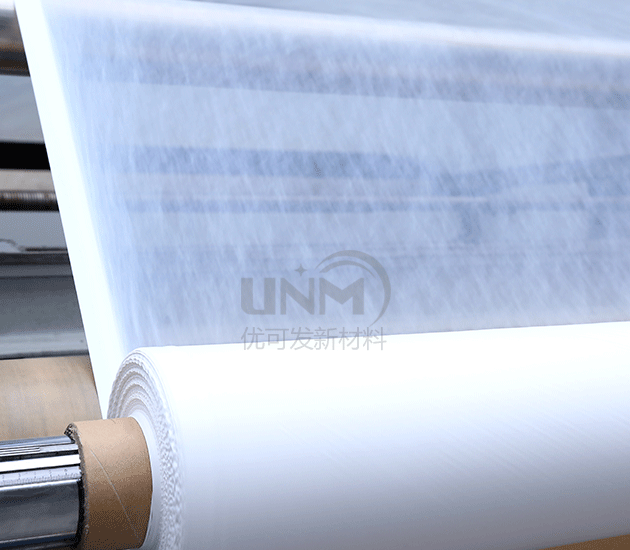

The PTFE aerobic compost membrane currently independently developed and produced is the core material of compost fermentation and is prepared using a two-way stretching process. . Special technology is used to modify the properties of the PTFE membrane, and then nanotechnology is used to add carbon particles into it, so that the film has the functions of isolating the volatilization of heavy metals and preventing the spread of odors. The harmful substances in the waste are changed through fermentation, and because the membrane has good air permeability, the gas generated during the fermentation process can be discharged through the micropores, with a pore size as small as 0.1-1 micron and a high porosity. Interested parties can enter the store for consultation and purchase!

</p