The shortage of fresh water resources has become a major problem in today’s society, and desalination is undoubtedly one of the ways to source fresh water. The main methods to obtain fresh water from seawater or brackish water are: electrodialysis, evaporation, multi-stage distillation and reverse osmosis. Membrane distillation technology, which has developed rapidly in recent years and combines distillation and membrane methods, has been successful in the application of seawater desalination and is expected to become a new method of producing fresh water cheaply and efficiently. Utilizing the waste heat of seawater used in industry or heating seawater with industrial waste heat for membrane distillation seawater desalination has the advantages of low cost, simple equipment, easy operation, and low energy consumption.

Membrane distillation is a membrane separation process that uses a hydrophobic microporous membrane and uses the vapor pressure difference on both sides of the membrane as the driving force for mass transfer. It can be used for distillation and desalination of water to remove volatile substances from aqueous solutions. For example, when aqueous solutions at different temperatures are separated by a hydrophobic microporous membrane, due to the hydrophobicity of the membrane, the aqueous solutions on both sides cannot pass through the membrane pores and enter the other side. However, due to the high water vapor pressure at the interface between the aqueous solution on the warm side and the membrane, On the cold side, water vapor will pass through the membrane pores from the warm side to the cold side and condense. This is very similar to the evaporation, mass transfer, and condensation processes in conventional distillation, so it is called a membrane distillation process.

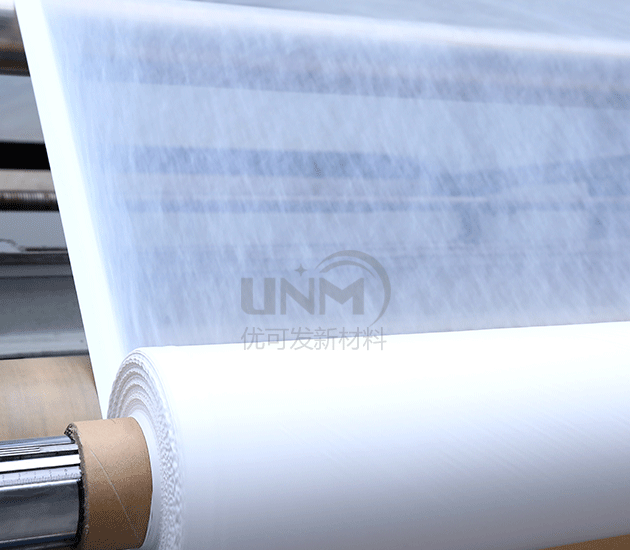

ptfe hollow fiber membrane is the core material of the membrane distillation process. The pore-forming mechanism of this material is through extrusion, shearing, Under the action of stretching, PTFE resin particles become entangled and initially fibrillated; further stretching can cause the microfibers in them to elongate, and ptfe hollow fiber membrane forms microfibrils-nodes. Pore structure.

It is a high-tech enterprise focusing on the research and development, production and sales of ptfe hollow fiber membrane, with an area of nearly 8,000 square meters. Factory area, professional production equipment and strong scale. Moreover, we have a full set of advanced production equipment and testing instruments, as well as a complete pre-sales, sales and after-sales service system. If you are interested, please enter the store for consultation.

</p