There are many types of air filters, with different filtration characteristics and application fields. The PTFE membrane material produced is widely used in filters. Let’s talk about PTFE. Characteristics and application fields of filters and the material PTFE plate and frame filter membrane.

PTFE filter is made of polytetrafluoroethylene Made of vinyl fluoride plate and frame filter membrane. It has the characteristics of high efficiency, low pressure loss, large dust holding capacity, tough filter paper, good sealing, compact structure, easy installation, low resistance, low operating cost and long service life. It can capture particles above 0.3μm very well. , the efficiency is over 99.99%, and there is also PTFE-coated filter material containing bacteriostatic (sterilizing) agents, which can well inhibit the growth of microorganisms in the filter material, prevent secondary pollution of the filter, and achieve the purpose of protecting the environment.

The design of the filter paper pleats combines efficiency with minimal resistance, providing a variety of thickness and size combinations , can meet a variety of application requirements. Polytetrafluoroethylene frame filter membrane The production process ensures the space and height of the pleats, thereby reducing “blind spots” and facilitating the continuous and even passage of gas through the filter. The pleat design allows air to pass through the filter The entire depth range of the filter makes good use of the filtration function of the filter paper.

This material offers significant advantages over traditional fiberglass filter paper, such as extremely low chemical vapor spread properties, more uniform fiber distribution, smaller fiber diameter and pore size. These characteristics reduce the filtration resistance and improve the filtration performance, thus greatly reducing energy consumption. Longer service life, resulting in less frequent replacement of consumables.

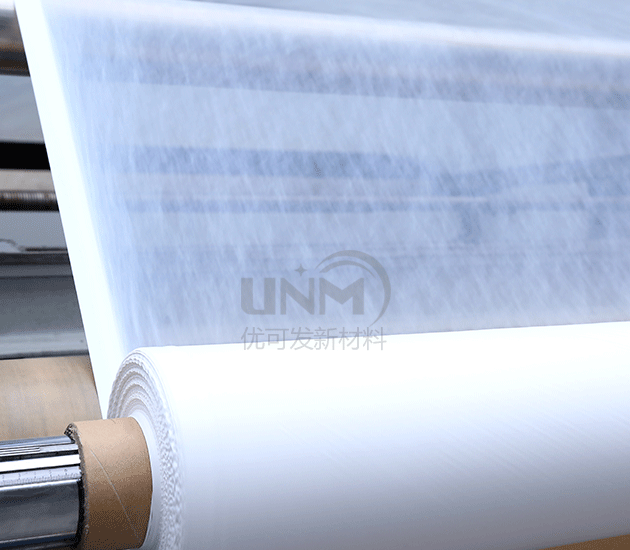

The polytetrafluoroethylene plate and frame filter membrane is obtained by thermally compounding the independently developed PTFE microporous film and imported non-woven fabric. It has a reliable filtration level of H13-U16, low wind resistance and low energy consumption, and is widely used in purification engineering systems. Interested parties can enter the store for consultation.

</p