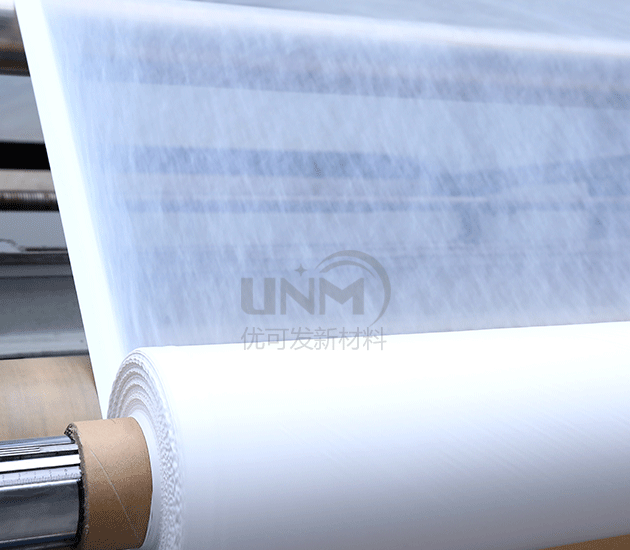

With the rapid development of modern medical and health industry and technology, clean technology is increasingly used in medical environments, and the cleanliness requirements for clean rooms are also higher. The polytetrafluoroethylene plate and frame filter membrane is composed of a self-developed ptfe microporous membrane and two layers of imported non-woven fabrics. It has a filtration grade of H13-U16. Low wind resistance and low energy consumption. It is widely used in clean room filtration, photovoltaic, electronics, LED display and other industries.

Purification workbenches are typically classified based on the number and size of particles allowed per unit volume of air in a specific period of time. This has to do not only with the quality of the filter, but also with the airflow within the housing.

Polytetrafluoroethylene plate and frame filter membraneUses airflow to filter fiber micropores or narrow, tortuous filter channels to produce multiple The collision causes the dust particles to be blocked or adhered to the filter element, thereby achieving the air purification effect. The emergence of clean workshops has greatly improved the quality of products in these industries, and has gradually begun to meet people’s daily needs. Clean workshops have also become essential infrastructure in some industries. But how to achieve the high filtration requirements of clean rooms? PTFE high-efficiency filter paper has the performance characteristics of high filtration efficiency, waterproof and breathable. It can filter out particulate impurities in the clean room and fully meet the purification requirements of clean room filtration.

For a uniform flow clean room, or laminar flow clean room, the average wind speed is crucial, because the free diffusion speed of dust is 0.15~0.2m/s. If the average wind speed cannot suppress the dust diffusion speed, no matter how good the filter is, it will be useless. For non-uniform flow clean rooms, the average wind speed is much lower than the diffusion speed of dust, and the air supply only plays a “dilution” role. Since these clean rooms have relatively many operators, equipment and production processes generate large amounts of dust, the filters Efficiency is no longer the decisive factor in cleanliness, because the worst high-efficiency filter efficiency will be 99.97%, which is enough to meet the requirements of “diluting” indoor dust concentration.

PTFE plate and frame filter membrane Compared with glass fiber and electret filter materials, it can achieve better The balance between wind resistance and interception rate has different levels of filtration such as ULPA, HEPA and other levels, which can meet the needs of different customers for filtration precision. The material is resistant to strong acids and alkalis and has good chemical resistance. The product itself will not degrade in performance due to cleaning, can be reused, and has a high utilization rate of resources.

As a high-tech fluorine material enterprise, it is committed to developing and manufacturing ptfe filter materials. The polytetrafluoroethylene frame filter membrane developed by it can provide core materials for filtration in clean operating rooms. Interested parties can enter the store for consultation. We will serve you wholeheartedly!

</p