The operating room that needs the most clean environment in the hospital is often the operating room, because if the patient becomes infected during the operation, it will have serious consequences. There are three main ways of surgical infection: direct contact infection, patient’s own infection, and infection caused by airborne germs falling into the wound. It is necessary to usepolytetrafluoroethylene plate and frame filter membrane to filter the air. It is understood that 25% of wound infections originate from germs in the air.

Basic composition of a clean room The general composition of a clean room includes: 1. Ceiling system: including suspension rod (Ceilingrod), outline beam ( I-Beam or U-Beam), ceiling grid beam (Ceilinggrid or Ceilingframe). 2. Air conditioning system: including air chamber, filter system, windmill, etc. 3. Partitional wall: including windows and doors. 4. Floor: including elevated floor or anti-static Shumei floor. 5. Lighting equipment: including fluorescent lamps, yellow lamps, etc.

Generally, the air purification in the operating room relies on the air inlet system to squeeze the air flow into the air like a “piston”, and the air flow passes through the primary filter. , and then through a medium-efficiency filter or a high-efficiency or ultra-high-efficiency filter. The filter material intercepts bacterial dust in the airflow and then transmits the clean air into the clean room, so that the air dust in the clean room quickly reaches the corresponding clean room standard requirements.

The air handler fresh air treatment air conditioning box provides the necessary fresh air for the clean room. The multi-circulation air conditioning box sends air into the clean room through the air supply duct and then through the ULPA filter or HEPA filter. On the ceiling of the clean room with cleanliness levels of Class 10 and Class 1, these filters are usually 100 %cover. The vertical one-way airflow passes downward through the clean room, passes through the overhead floor tiles with holes, enters the return air space below the floor, and then upwards through the vertical return air duct into the ceiling return air static plenum. Then, the air enters the circulating air conditioning box again, and the above air circulation repeats again.

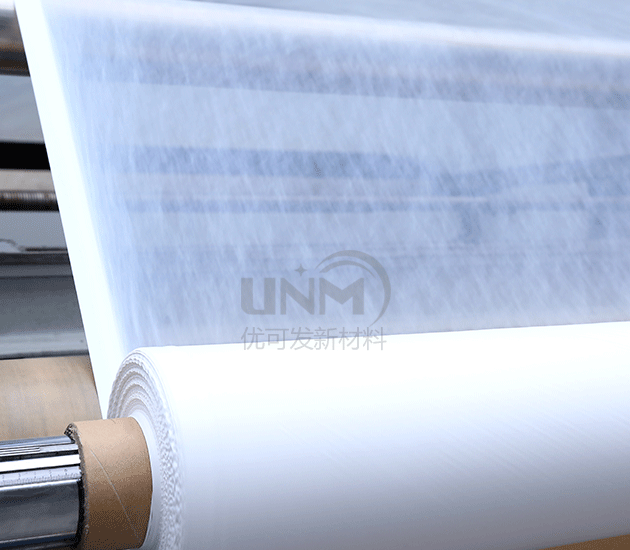

For filtration applications in clean room operating rooms, an air purification filter material –Polytetrafluoroethylene is specially developed Plate and frame filter membranes and PTFE plate and frame filter membranes have a three-layer structure. The middle is a PTFE microporous film, and the upper and lower layers are covered with imported non-woven fabrics. It has low wind resistance and is easy to clean. Surface dust can be removed by backflushing and reused. As the core material of clean room purification equipment, it has high filtration accuracy.

As a high-efficiency separation filtration material design solution provider, we are committed to protecting personnel and processes by developing and manufacturing high-quality PTFE air filtration membranes and composite materials. and system. And for clean room applications, a high-efficiency air filter material for clean rooms has been specially developed – Polytetrafluoroethylene plate and frame filter membrane, which can be used as the core filter material of high-efficiency air filters in clean rooms and has H13- U16-level reliable filtration grade, low wind resistance and low energy consumption, and is widely used in semiconductor, electronics, flat panel display, photovoltaic and other industries. Interested parties can enter the store for consultation.

</p