Skiing has always been a sport that people have always loved. Skiing consumes a lot of physical energy. Many beginners have not yet mastered skiing skills. Yes, a lot of energy is spent in unnecessary places, which is very strenuous. You will sweat a lot during skiing, and you will be sweating profusely when you are busy. General thermal underwear is mainly made of cotton and has weak perspiration wicking function. It is not recommended to wear this type of thermal underwear for skiing. Imagine it’s freezing and snowy outside, and your underwear is soaked inside. It’s cold outside and hot inside. Not only is it so sour, but it’s also easy to catch a cold. Therefore, professional close-fitting ski clothing is an important guarantee for a good skiing experience. This is also inseparable from the powerful role of clothingptfe composite fabric.

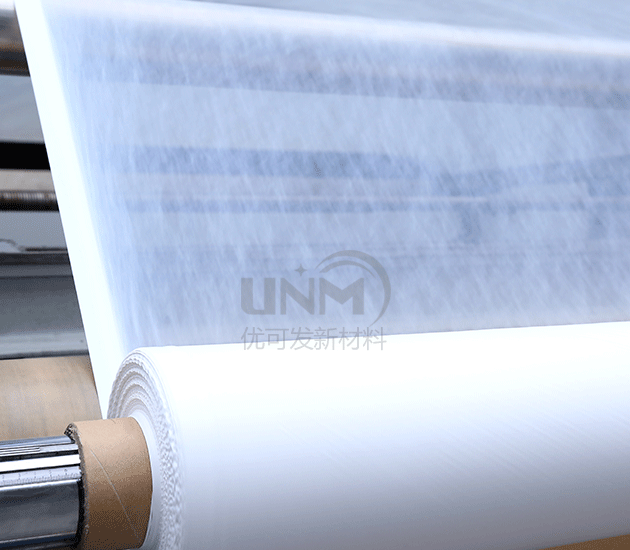

The composite fabric we are talking about is made of fine fibers that undergo specific textile processing and special dyeing and finishing, and then ” The new fabric processed by “composite” equipment has high cleaning ability and good warmth and breathability.

Expanded polytetrafluoroethylene, abbreviated as e-PTFE, is a porous, low-density and high-toughness PTFE dispersion resin that is expanded through a production and processing process. Material. Although expanded PTFE has changed in structure, it still maintains the excellent chemical properties of PTFE. It also expands the use temperature range, improves mechanical strength and adds some new characteristics, such as improved creep resistance and reduced expansion coefficient. Small, it has porosity, breathability, hydrophobicity and extremely high toughness. These excellent properties broaden its application range.

The expanded polytetrafluoroethylene film can be combined with ordinary fabrics to make waterproof and breathable laminated fabrics that can be used as clothing ptfe composite fabrics. The material has approximately 9 billion micropores per square inch, with a pore diameter between 0.2-0.3μm and a micropore area of up to 80%. The size of each micropore is 20,000 times smaller than a water droplet and 700 times larger than a water molecule. Water droplets cannot pass through but water vapor molecules can pass freely, achieving waterproof, sweat-wicking and breathable effects. At the same time, due to its high strength, low shrinkage, non-stickiness and other excellent properties, e-PTFE fiber has become a fabric for outdoor sportswear. It is also often made into firefighting suits, space suits, protective suits, combat uniforms, sleeping bags and lightweight tents.

Clothing ptfe composite fabric is a new type of textile fabric, which is composed of polymer waterproof and breathable material (PTFE membrane) plus fabric Compounded. And while we strengthen the air-tightness and water-tightness of the fabric, its special breathability can quickly discharge water vapor inside the structure, avoid the growth of mold in the structure, and keep the human body dry at all times, solving the problems of breathability, windproof, waterproof, and warmth retention. !

It is a clothing ptfe composite fabric manufacturer that integrates production, sales and customization. The company has advanced PTFE film production lines and composite production lines. Strict management system provides users with high-tech, high-quality, high-performance and high-level products. Interested parties can enter the store for consultation.

</p