With the increasing seriousness of environmental pollution and the strengthening of people’s environmental awareness, air quality has become the focus of global attention. Now people realize that the air filtration system not only protects mechanical equipment, but also To protect people, H13 high-efficiency filter material is the material for air filtration. Therefore, the application range of air-conditioning primary filters is getting wider and wider. Many products are processed in clean rooms, which is what we often say. In the dust-free workshop, the main function of the clean room is to control indoor pollution. Without a clean room, mass production of pollution-sensitive parts is impossible, and the clean room high-efficiency filter plays a big role in this space.

Clean room primary filter is mainly used to filter dust particles above 5um, and is mainly used in commercial and industrial ventilation systems. Air conditioning system etc. Its working principle is: when the air to be filtered enters the equipment, flows through the filter material of the filter, then flows out from the air outlet surface, and enters the lower-level filtration or ventilation duct. The particulate impurities in the air have been trapped by the filter. However, as this operation continues to cycle, more and more particles are intercepted, the filtering resistance will become greater and greater, and the passing air volume will become smaller and smaller.

The main source of dust in a clean room is people and equipment. In comparison, the amount of dust entering the room through a high-efficiency filter is much less. If the ventilation parameters are the same, there will not be much difference in the cleanliness of the clean room between using a 99.9999% filter and a 99.99% filter. For a uniform flow clean room, or a laminar flow clean room, the average wind speed is crucial because the free diffusion speed of dust is 0.15~0.2m/s. If the average wind speed cannot suppress the dust diffusion speed, no matter how good the filter is, it will no good. HEPA filter paper is currently the most common type of air filter. It can purify particles above 0.3 microns, with a removal effect of 99.7%. Especially for PM2.5, the effect is even more obvious, and it is very recognized by consumers. filter.

Conventional filter materials carry dust that is easily adhered to, and the dust is not easy to fall off during cleaning, resulting in low dust cleaning efficiency and short-term dust emission. The H13 high-efficiency filter material has extremely fine, smooth, low friction coefficient, dust-free, hydrophobic, and stable chemical properties on the surface, so the dust deposited on the surface can be easily cleaned, even wet dust can be removed. Very difficult to adhere to.

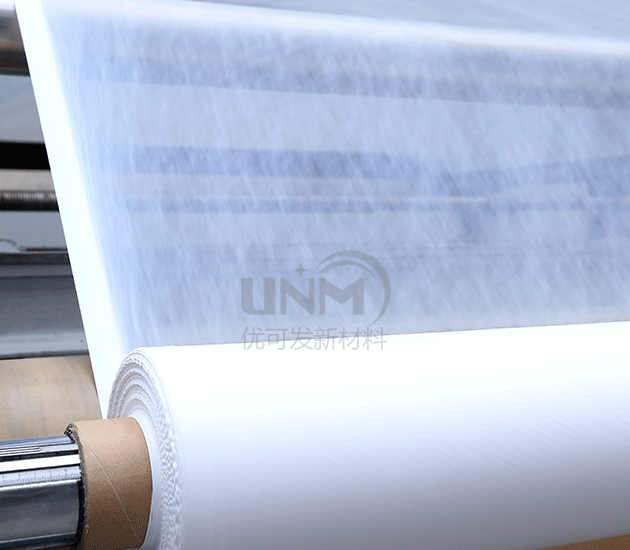

The microporous membrane is a three-dimensional mesh with no through holes and a cross microporous structure. This microporous filter material can capture most dust particles. This prevents dust from entering the membrane through the surface of the membrane. This filtration method in which only gas passes through and dust is trapped on the surface of the membrane is called surface filtration. The mechanism is very simple. The pore size of the membrane is smaller than the pore size of the particles to be filtered.

H13 high-efficiency filter material is the core filter material of the fan filter unit. It has strong hydrophobicity, chemical resistance, and hydrophobicity. It has good performance and low wind resistance, and can achieve high dust removal efficiency. For some very small particles with a diameter of 0.1um-0.3um, the filtration level can reach H13-U16. In addition, H13 high-efficiency filter material can achieve very low emissions by intercepting various types of dust generated during the production process of enterprises. If you are interested, please enter the store for consultation.

</p