In industrial dust removal, we often use a variety of filters to meet different needs, so how should we choose when faced with such a variety of filters? ? When choosing a filter, the first thing to consider is the filter material. The editor here recommends Teflon high temperature membrane.

With the improvement of human environmental protection awareness, as well as the increasing requirements for energy saving, consumption reduction and increasingly tight land resources, filter cartridges Dust collectors have gradually become an upgraded substitute for industrial bag dust collectors and are increasingly used in the dust removal industry at home and abroad. Compared with traditional bag dust collectors, cartridge dust collectors have the characteristics of large filtration area, low resistance, low emissions, small size, and long service life, and have become a new direction for the development of industrial dust collectors.

The filtration mechanisms of filter materials mainly include: interception effect, gravity effect, inertial effect, diffusion effect, electrostatic effect, etc. Interception effect: The arrangement inside the filter material is intricate and intertwined. The average pore size of the filter material is small. Particles with a particle size larger than the pore size of the filter material cannot pass through the gaps between the filter material layers and are intercepted. Gravity effect: Large particles of dust have a greater gravity and may settle directly without filtering material, or the particles attached to the filtering material may agglomerate, increase their gravity, and detach from the filtering material after being vibrated. Inertial effect: Powder particles move with the airflow, and the airflow encounters obstacles and detours. The dust deviates from the direction of the airflow due to inertia and hits the filter material layer and is collected. The larger the particles, the stronger the inertial force, and the greater the possibility of being filtered. Diffusion effect and electrostatic effect: Fine dust hits the filter material layer, and the gravitational force between the dust and the surface of the filter material causes it to stick to the filter material and be filtered out. Particles with smaller diameters undergo Brownian motion and collide with each other. Particles with smaller diameters collide with each other or are frictionally charged with the filter material. The particles are attracted and captured. For large particles of dust, the first few filtration mechanisms are mainly used, and for smaller particle sizes, the latter ones are mainly used. Multiple filtration mechanisms work at the same time, so that most of the dust will be filtered out, and the dust removal efficiency of the dust collector will be higher.

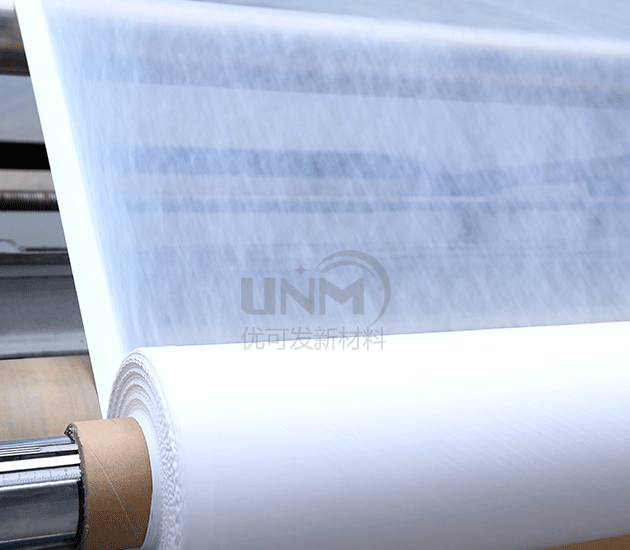

Teflon high-temperature membrane is the core filter material of the cartridge dust collector, and the dust removal efficiency can reach more than 99.99%. The pore size of the film can reach 0.3um, which can capture most solid particles and liquid droplets. The dust layer formed by filtration is easy to split, and the filter material has good air permeability. Teflon high-temperature membrane is hydrophobic. The adhesion between the dust layer and the filter material is small and it is easy to split. It can fall off by its own weight without external force, and the dust cleaning effect is good.

Teflon high-temperature filmThe manufacturer has a full set of advanced production equipment and testing instruments, and complete pre-sales, sales and after-sales services service system. Teflon high temperature membrane has products widely used in various fields. Interested parties can enter the store for consultation.

</p