Polytetrafluoroethylene microporous membrane has a special node-microfiber structure. In the 1960s, DuPont began to use single It is prepared by the axial stretching method, but the porosity and mechanical properties are insufficient, and the practical application fields are limited. In 1973, Gore successfully developed a product with high porosity, high air permeability and excellent mechanical properties using biaxial stretching technology. The PTFE microporous membrane marks that the industrial application of PTFE microporous membrane has become technically mature. After decades of development, among the current production processes of PTFE microporous membranes, only products obtained by the biaxial stretching method have better microporous structure and mechanical strength.

Polytetrafluoroethylene microporous membraneThe main preparation processes are as follows Four parts: the mixing and aging process, the embryo making and pushing process, the degreasing longitudinal drawing process and the transverse expanding process, and then a PTFE microporous membrane with a special microporous structure is obtained, including pushing, longitudinal drawing and transverse drawing. During the process, the PTFE microporous membrane will undergo varying degrees of fibrosis, that is, the structural distribution of nodes and microfibers will change differently as the process progresses, and then the special microporous structure of the PTFE microporous membrane will be formed.

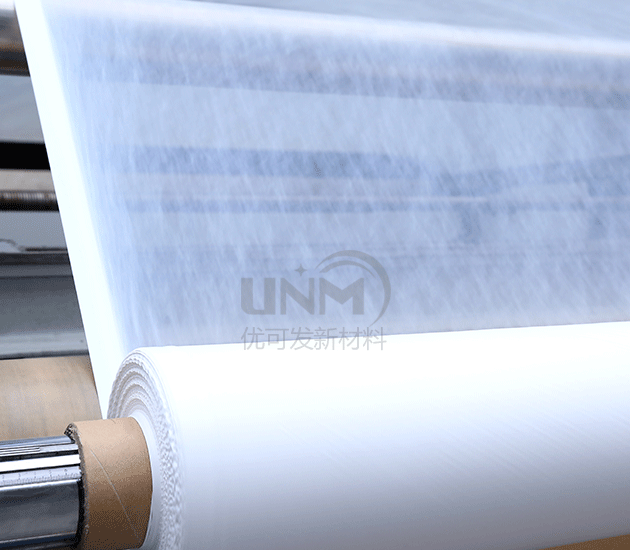

It is a polytetrafluoroethylene microporous membrane material manufacturer that specializes in R&D, production and sales. Our company is different from other manufacturers. Our company can according to the user’s requirements. By optimizing the combination of key technical parameters such as speed ratio, pressure ratio, and operating temperature, the air permeability, thickness, and void ratio can be adjusted online according to the ratio and pore-forming medium to meet your different requirements. Interested parties can enter the store for consultation.

</p