Polytetrafluoroethylene filter membrane can be used for atmospheric dust removal, air purification, etc. The membrane pore size can be controlled to 0.2um, and the porosity can reach more than 88% , combined with various filter materials such as needle felt, machine-made fabric, non-woven fabric, glass fiber, etc., to obtain a coated filter material with surface filtration performance. The PTFE coated filter material has high peel strength, large air permeability, and uniform pore size distribution. Features. As a dust bag or pleated dust filter cartridge, it is installed in the dust removal equipment to quickly and well intercept very fine dust measured in microns. The dust removal efficiency can reach more than 99.99%, the service life is up to 3 years, and the air permeability can reach 3-6m /min, it is the most advanced air filter material in the world. A good choice for various vacuum cleaners, air filters, air purification equipment, high-efficiency air filters, etc.

PTFE microporous membrane has excellent temperature resistance, Low temperature resistance, melting point is 327 degrees Celsius, decomposition temperature is 415 degrees Celsius, and can be used for a long time in the range of 200 to 260 degrees Celsius. PTFE material is highly hydrophobic, has low surface energy, and has good non-adhesion. It is easy to remove dust accumulated on the surface of the material, so it can be rinsed with water to restore its performance and achieve repeated use, greatly extending its service life.

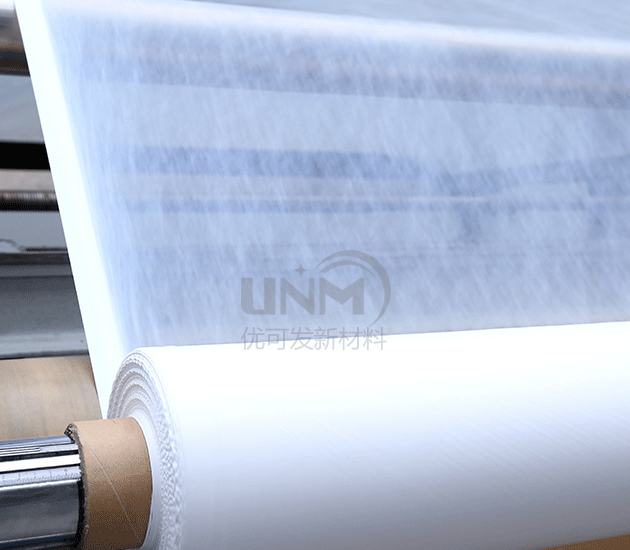

The polytetrafluoroethylene microporous membrane produced by the manufacturer uses imported raw materials and has a full set of advanced production equipment. , has an advanced clean room and an independent composite slitting workshop to ensure the production quality of ptfe film; it uses imported production testing instruments to test the quality of ptfe film, and has passed SGS testing and certification, as well as ISI testing and certification. Interested parties can enter the store and contact us.

</p