The melt-blown material of ordinary protective masks intercepts particulate matter based on the principle of electrostatic adsorption. As the use time increases or the temperature and humidity change, its filtration efficiency decreases significantly. Masks made of polytetrafluoroethylene microfiltration membrane composite fabric are based on the principle of physical barrier. The filtration efficiency will not decrease due to moisture or with increasing use time, andpolytetrafluoroethylene Microfiltration membraneHydrophobic and moisture permeable, there will be no water vapor retention, low breathing resistance, and comfortable to wear.

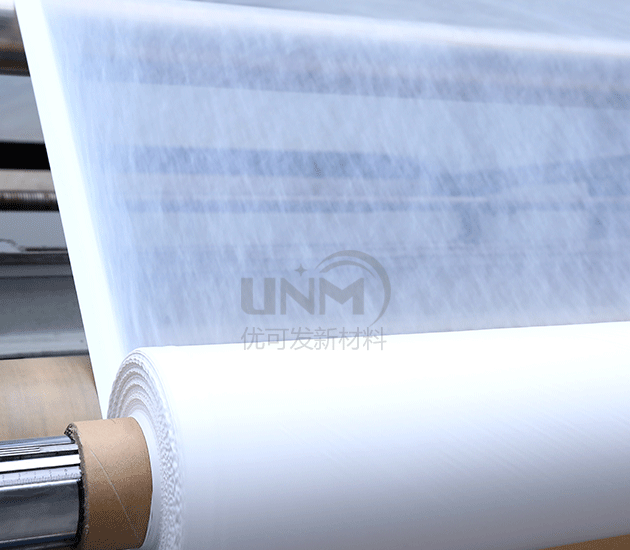

The e-PTFE film produced from polytetrafluoroethylene resin has a network structure and can reach billions of micropores per square inch. , this structure can be used to achieve the characteristics of being light, thin, hydrophobic, and windproof. When combined with ordinary fabrics through a lamination process, it can achieve perspiration, breathability, and windproof effects. It is widely used in protective clothing, bandaging textiles, and fire protection clothing. , outdoor equipment.

The polytetrafluoroethylene microfiltration membrane produced by the manufacturer uses imported raw materials and has a full set of advanced production equipment. , has an advanced clean room and an independent composite slitting workshop to ensure the production quality of ptfe film; it uses imported production testing instruments to test the quality of ptfe film, and has passed SGS testing and certification, as well as ISI testing and certification.

ePTFE membrane technology has always been the core of the business and plays an indispensable role in many fields such as biopharmaceuticals, equipment, food and beverages, semiconductor manufacturing processes, and communications. Role, the pore-forming ability ranges from 0.1μm to 1μm, providing functional solutions such as fine filtration, removal of small bacteria and viruses, hydrophobic breathability, and sound transmission. Interested parties are welcome to enter the store and contact us.

</p