Polytetrafluoroethylene microfiltration membraneA polytetrafluoroethylene (PTFE) microporous membrane prepared by a biaxial stretching process. Its microporous structure is Node – the fibers are staggered, with uniform pore size and high porosity. It is a filter material with excellent performance. Has the following characteristics.

Pure PTFE material membrane has the characteristics of temperature resistance, corrosion resistance and aging resistance. The pore size is small and uniform, and the dust interception rate is high, reaching more than 99.99995%; the porosity is high (≥85%), and it still has high air permeability under high filtration. The surface energy is low and has good non-adhesion. Through pulse backflushing or cleaning, the dust on the surface can be easily removed, the performance can be restored, and the service life can be greatly extended.

Polytetrafluoroethylene microfiltration membrane has a large number of micropores, which significantly reduces its relative density. Generally, the relative density of PTFE products is The density is about 2.15, while the relative density of expanded PTFE products can be less than 0.1, which means that the porosity reaches about 96%. Because EPTFE has a large number of micropores, it has new functions without losing its original excellent properties, namely separation function, softness, elasticity and sealing. New Material Technology Co., Ltd.’s best-selling products are PTFE microporous films and more related derivative products, which are suitable for air purification filtration, food filtration, clean room filtration, industrial dust removal filtration, electronic hydrophobic breathability and clothing fabrics, etc. The products are sold overseas.

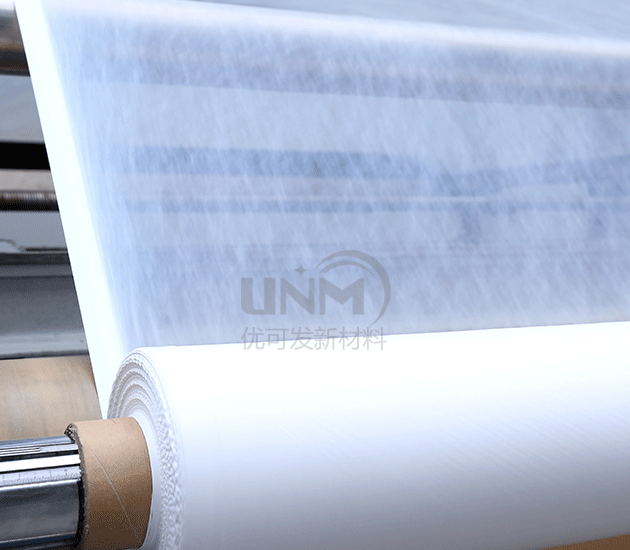

High-efficiency filtration filter paper obtained by thermally compounding the self-developed polytetrafluoroethylene microfiltration membrane and imported non-woven fabric, with H13- U16-level reliable filtration grade, low wind resistance and low energy consumption, it can be widely used in clean room filtration, frame filter (FFU), electrical chips, LED displays and other fields. Interested parties can enter the store for consultation and purchase!

</p