In recent years, ptfe microporous membrane manufacturers have developed and launched various achievements, such as filter materials, ptfe microporous membranes, etc. These products have improved people’s quality of life in large or small ways, and also fully improved people’s living standards.

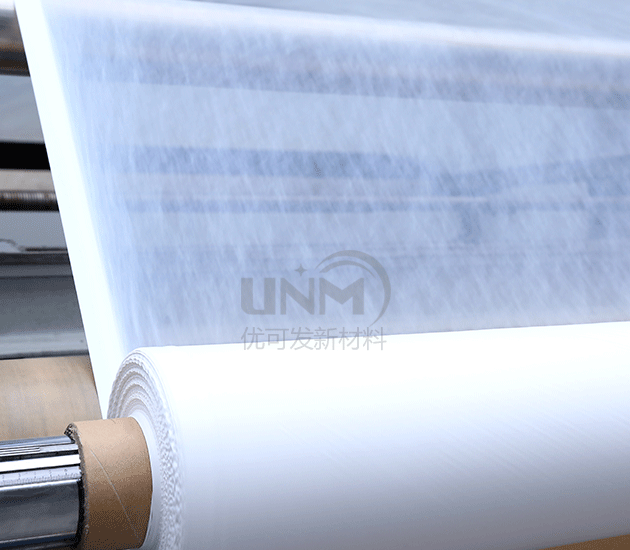

The expanded PTFE microporous membrane has excellent chemical corrosion resistance, high and low temperature resistance, and low friction coefficient. Hot pressing or adhesive compounding to the surface of traditional filter media can make film-coated composite filter media with special properties. Because the expanded PTFE membrane has many holes and small pore diameter (pore diameter is 0.3~10μm), ptfe microporous membrane manufacturer microporous membrane can intercept tiny dust particles, and the membrane surface is extremely smooth, making it difficult to A thick dust layer is formed, making cleaning easier. At present, expanded PTFE membrane filter materials have been widely used in flue filtration and hot air filtration in chemical plants, power plants, carbon black plants, cement plants, spray paint plants, etc.

ptfe microporous membrane manufacturer‘s products are generally divided into the following categories: air filter membrane, which can be used for atmospheric dust removal and air purification etc., it is a good filter material for various vacuum cleaners, air filters, and purification equipment; protective moisture-permeable microporous membrane, which is characterized by good wind resistance and warmth retention, and is widely used in fire-fighting, anti-virus, water-immersed clothing and outdoor sleeping bags, tents, etc.; Polymer Tetrafluoroethylene bubble-point membrane, this membrane is laminated on various fabrics and substrates using a special process to become a new filter material. The membrane has small pore size, about 0.2-0.5μm, even distribution, large porosity, and can maintain air While circulating, it can filter all dust particles including small bacteria to achieve purification and ventilation. Interested parties can enter the store for consultation and purchase!

</p