Down jackets, down quilts and other down products are increasingly favored by consumers due to their outstanding warmth and comfort properties. However, the biggest obstacle that plagues down products is the contradiction between the anti-drilling performance and breathability of the fabric. In order to obtain acceptable lint resistance, researchers in the textile industry have to reduce the breathability of fabrics as much as possible in order to obtain corresponding lint resistance. But in this way, the breathability, washability and variety of options ofePTFEclothingfabrichave been sacrificed.

Functional fabrics can isolate the human body from rain, snow, and chemicals in harsh environments, while also providing protection from the outside world. Transfer water vapor. The performance differences of water-repellent and breathable fabrics determine the subsequent application range. Structurally, it can be divided into microporous materials (including ePTFE clothing fabric, polyurethane PU microporous membrane, ultra-dense fabric, polyethylene PE porous membrane) and non-porous materials (thermoplastic polyurethane TPU hydrophilic and non-porous porous membrane), as well as microporous and non-porous composite materials (PTFE microporous membrane + PU non-porous membrane, fabric + hydrophobic treatment agent coating, PP + PE porous membrane + PP laminate composite).

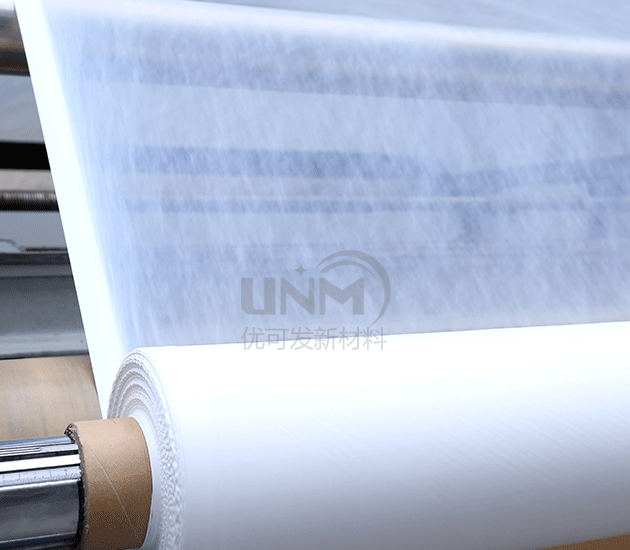

ePTFEClothingFabricThe main principle is to pull polytetrafluoroethylene Stretch to allow micropores to appear, and the diameter of the micropores must be controlled to be about 700 times that of water molecules, one 20,000th of a water droplet, and there are approximately 9 billion micropores in a Teflon clothing membrane per square centimeter. , such micropores are impermeable to water droplets, but sweat can be eliminated through the micropores in the form of molecules, thus achieving the purpose of water repellency and breathability. Interested parties can enter the store for consultation and purchase!

</p